Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check

Product Information

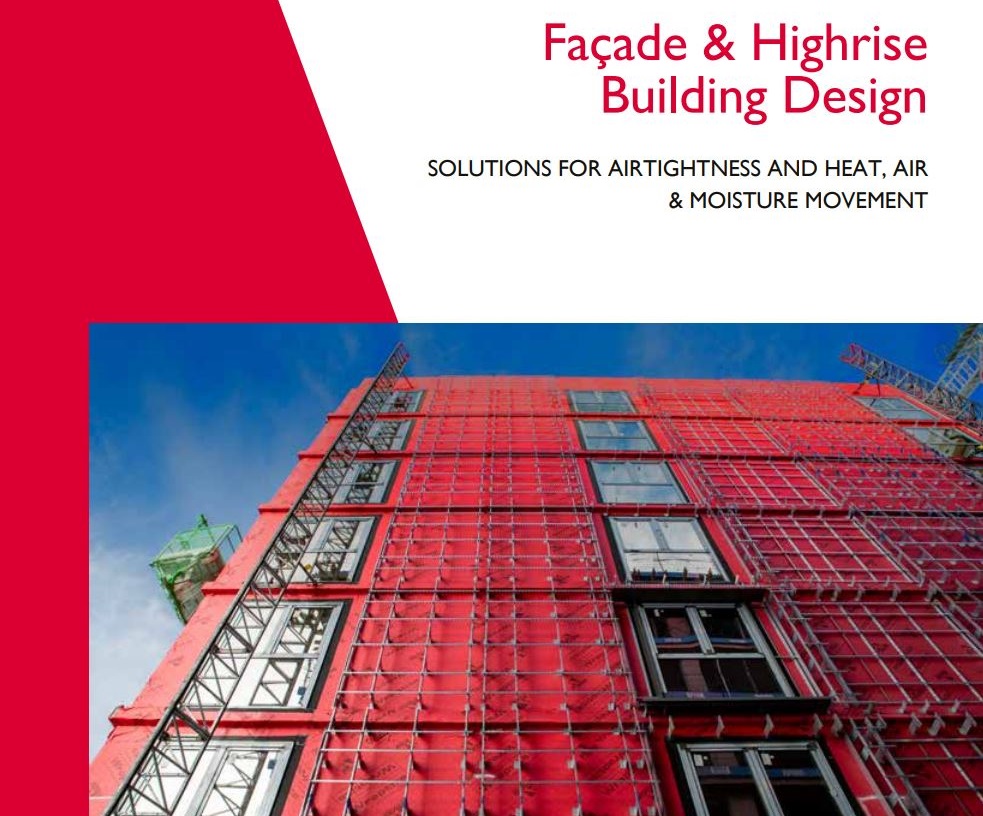

Facade Solutions Brochure

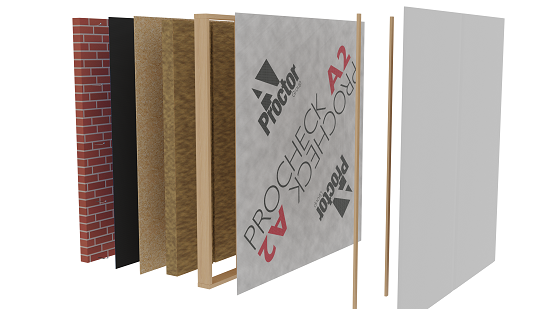

We offer a range of product solutions covering thermal, acoustic, ground gas, vapour control & airtightness, suitable for your commercial building. These are applicable for Steel, Concrete, Timber, CLT and Offsite

construction projects.

Our portfolio of specialist vapour and airtight membranes, combined with our extensive technical expertise, ensure that the correct balance of Heat, Air & Moisture Movement is achieved via the building envelope. Our patented externally applied airtight membrane system, Wraptite, offers commercial construction providers the ability to reliably and comfortably exceed current airtightness requirements.

Total Solution Capabilities

Our products are backed up by a dedicated team of technical experts, able to assist at every project stage from pre-planning to on site. We offer CAD detail reviews, installation guidance, condensation risk analysis,

WUFi calculations, U-Value calculations, ground gas system designs, telephone support & more. Our products also have a range of BIM Objects & Performance Specifications.

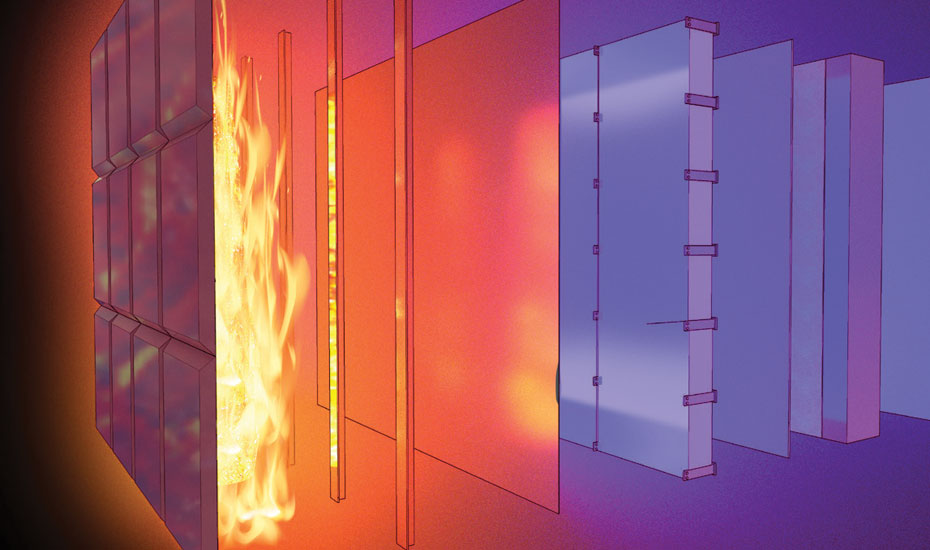

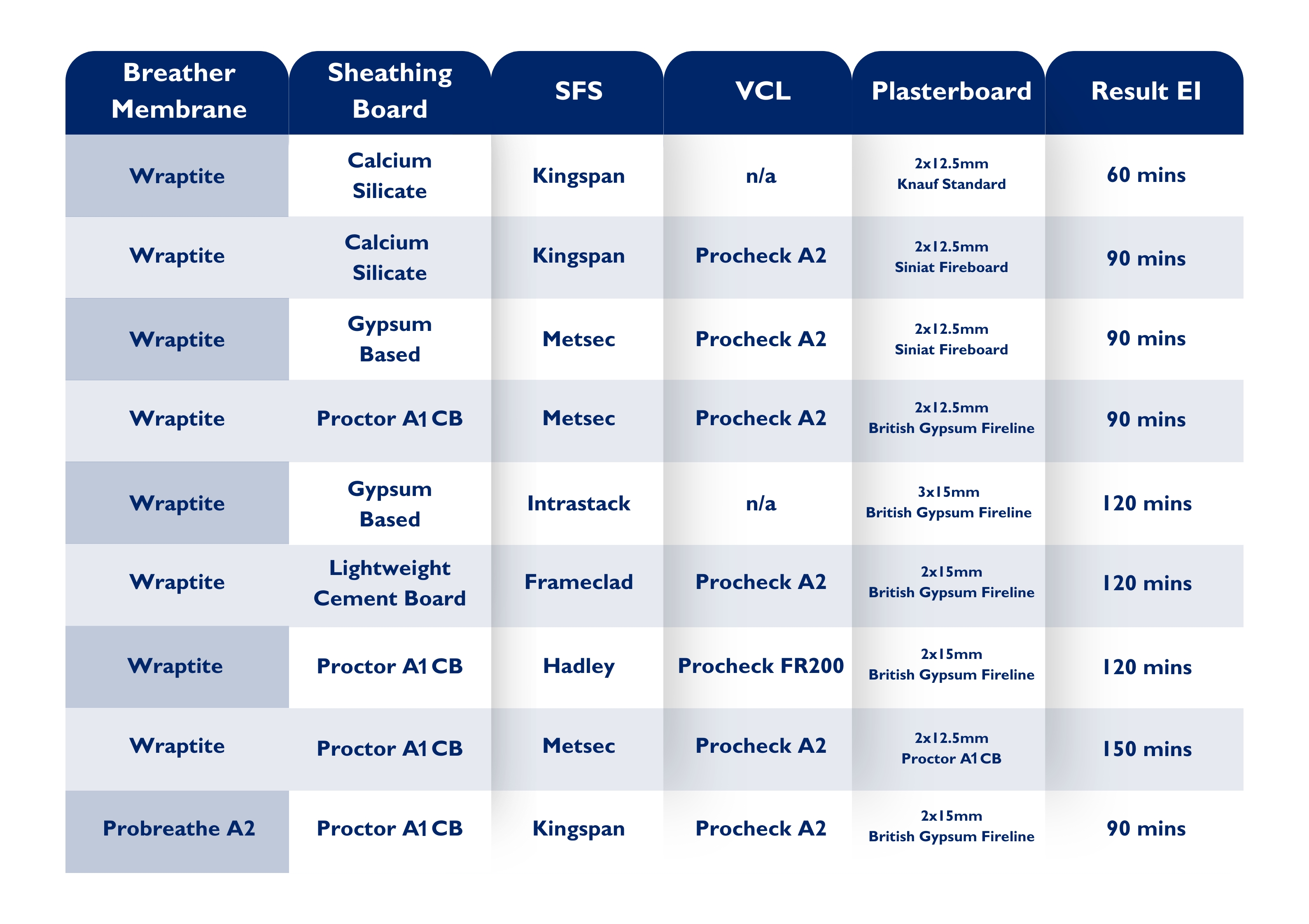

Through Wall Fire Testing

Through wall fire tests are crucial in evaluating the safety and integrity of buildings. The tests assess the ability of a wall to withstand fire while maintaining its integrity and insulation properties. The tests are conducted under controlled conditions, following specific standards and guidelines, to ensure accuracy and reliability.

Through wall fire tests reveal how well a wall can insulate against heat transfer during a fire. Good insulation properties are essential for preventing the spread of fire and maintaining safe temperatures within the building. The tests also provide data relating to the integrity and stability of the wall under fire conditions.

Building regulations often require specific fire resistance ratings for walls. By understanding how a wall performs under fire conditions, designers and specifiers can select materials and constructions that offer optimal fire resistance. Through wall fire tests provide the necessary data to ensure that the selected wall systems comply with these regulations.

RIBA - Air Leakage and Fire Performance in Facade Systems

This CPD aims to provide an overview of UK and Irish building regulations relating to the compliance of construction membranes, with respect to air leakage and reaction to fire. It will cover adjacent issues of moisture control and hygrothermal assessment, and the implications of air leakage strategies on both energy efficiency and ‘as designed’ vs ‘as-built’ performance. By the end of the presentation you should have a greater understanding of:

- Heat, Air and Moisture movement in building and relevant building regulations

- Hygrothermal Assessments, Dynamic vs Steady State methods

- Mechanisms and effects of air leakage on building envelopes

- Performance and location of membranes as air barriers in facade applications

- Fire test methods, classifications and BR135

- The relationships between hygrothermal and fire performance criteria and their implications

Standards & Building Regulations

Due to the performance requirements of certain critical, flexible components within the external façade, such as breather membranes, the ability to achieve a non-combustible classification is inhibited by the nature of the materials from which they are made.

This was understood by the regulatory writers and therefore a list of exempt components has been included in Approved Document B to accommodate such products. Manufacturers are investing time and money into this area in order to provide an achievable fire classification without impeding the performance of the product.

In the amendment to Document B in November 2018 the required fire classification for breather membranes is stated to be:

“Membranes used as part of the external wall construction should achieve a minimum classification of European Class B-s3,d0”

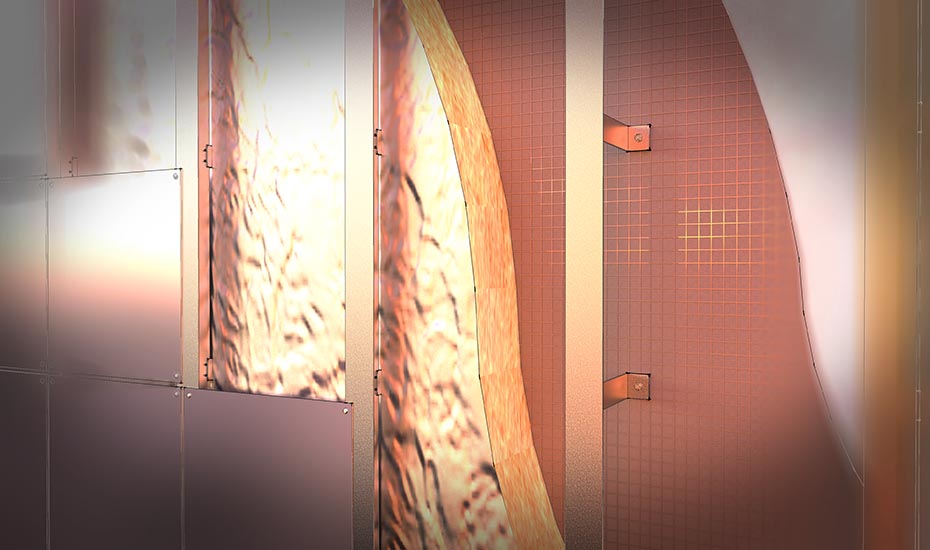

Usually breather membranes are mechanically fixed on low rise and taped on high rise. These membranes tend to shrink away from fire, however standard tests utilise a single focused burning flame which is widely challenged as the correct way to test a membrane for this application, and is not reflective of a real time scenario.

There is a clear benefit to using a self-adhesive membrane due to the material being fully adhered to the substrate. Therefore, there is no air gap behind the membrane and the substrate, meaning no flames can pass up the back of the membrane, as could happen with a loose mechanically fixed product.

Membranes & Fire Performance

The increasing use of a self-adhered breathable membrane in high-rise development over A1 and A2 sheathing boards, has resulted in it being carefully considered in terms of performance in a fire context, which is of critical importance. Wraptite has therefore undergone classification to BS EN 13501-1 over a wide range of appropriate substrates

The results from these tests showed that Wraptite achieved a Class B-s1-d0, the highest classification that can be achieved from a polypropylene based membrane.

This performance allows designers to utilise the air leakage performance benefits of Wraptite with confidence, even in the most demanding of applications where fire safety is critical.

However, if using a membrane in the cavity, either on lower rise buildings, or in high rise to add further protection to the system, products which actively resist fire, such as Fireshield are ideal.

Fireshield is a more rigid mechanically fastened product compared to lighter weight polypropylene membranes, in part due to the nature of its glass fibre backing. The weight and robustness of the product makes it less likely to billow away from the substructure, forming air gaps behind when installed correctly.

Fireshield’s specialist coating eliminates fire spread across the surface of the membrane and it is fixed using mechanical fixings. The intumescent facing actively resists the spread of flame by preventing it from taking hold due to the ‘foaming’ effect (expanding when it interacts with fire).

The A. Proctor Group provide a number of Breathable Membranes and Vapour Control Layers which have in depth testing to ensure confidence in the performance of the products in situ.