In the design process of any building, project professionals will consult Building.

Regulations, Standards and Codes for information on fire safety and compliance. This process usually focuses on the level of life safety related to fire of occupants in and around a completed building only.

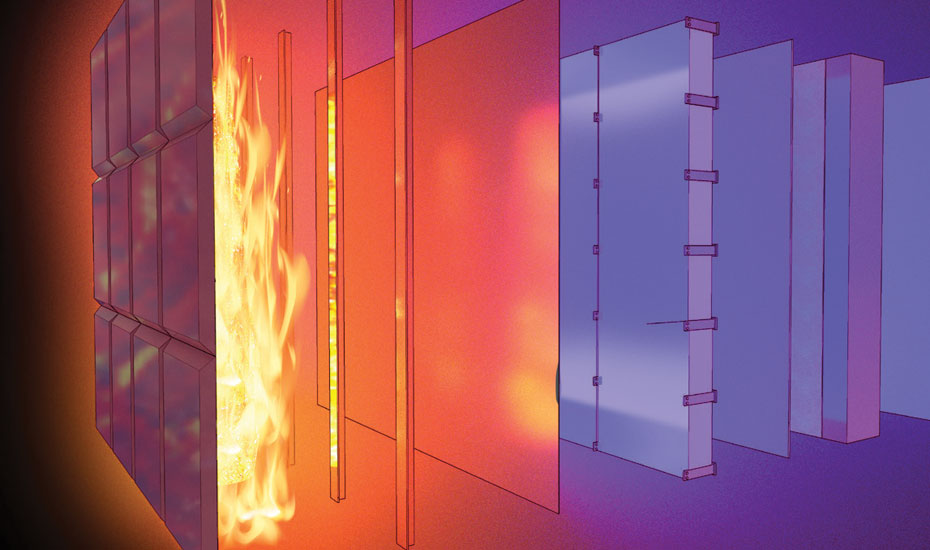

This is due to an absence of technical guidance in Building Regulations and Standards for fire safety during construction, specifically the determination of the safe fire space separation between buildings under construction and existing buildings outside the site boundary.

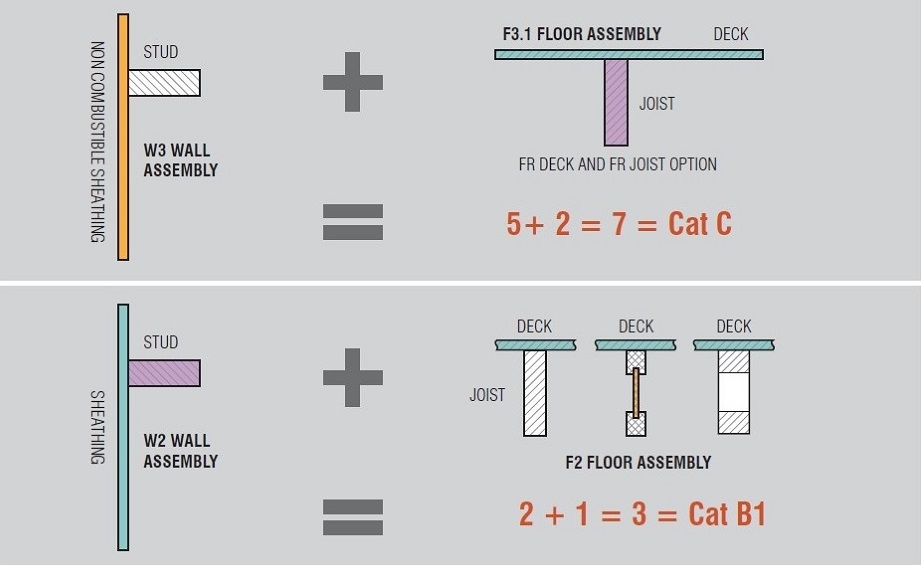

To address fire prevention while construction is happening, designers can consult the Construction(Design and Management) Regulations (2015) and, if it is a timber frame structure being built, extensive guidance published by the Structural Timber Association (STA). We will look at the STA’s guidance in greater detail in this document.