There is now more emphasis on not only the quality of materials being used but also the design performance of ventilation systems along with installation and verification.

It is now recommended that installation teams attain Construction Skills NVQ Level 2 qualifications in gas membrane installation as per CIRIA C735 Good practice on the testing and verification of protection systems for buildings against hazardous ground gases. There has been more emphasis on the installation of gas membranes.

The penetrations are classed as the weakest point of the installation and the following areas should be paid extra care and attention:-

Corner Units

- Corner details are one of the areas that are difficult to seal correctly and we would suggest to use the Preformed Corners

- Preformed Corners are sealed in place by either welding or taping to form a gas tight seal.

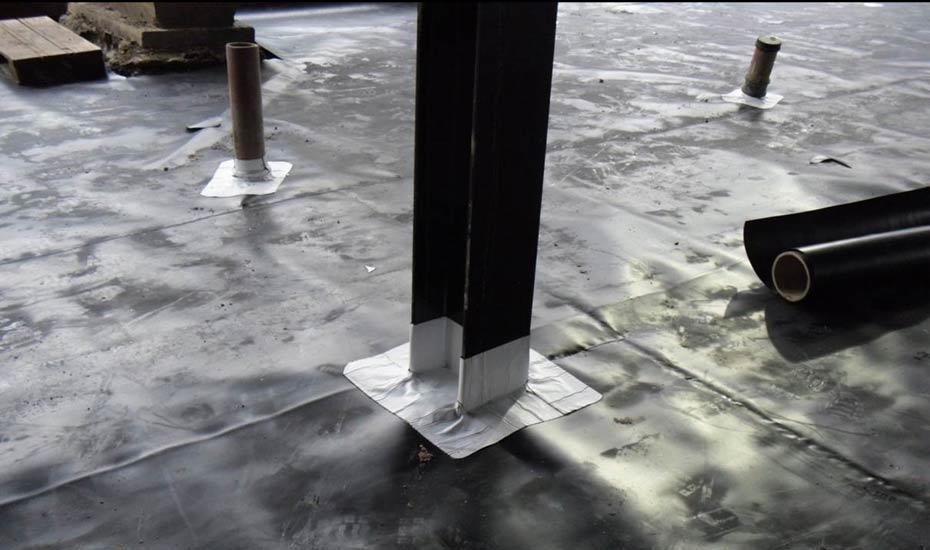

Stanchions

- Dress the Stanchions with Protech GM Self Adhesive Flashing

- Apply 2 coats of Protech Bitumen Primer prior to the area to be covered by the Protech GM Flashing

- Ensure that the Protech GM Flashing is overlapped onto the Protech Gas Membrane

Pipe Penetrations

- Pipes can be sealed with the use of our Preformed Protech GM Tophats.

- Ensure that the release paper of the Protech GM Tape is removed completed once the Protech GM Tophat is in place to ensure a good seal.

- Best practice is to weld into position.

- Use a strip of Protech GM 150mm Flashing to the top of the Protech GM Tophat rather than using a Jubilee Clip as this can create distortion to the pipe.