If the desired outcome is a low-carbon building, or energy performance assessed by post-occupancy monitoring, then contractual arrangements need to reflect it. A contract based on meeting building regulations for the lowest price offers no incentive or additional fees for a contractor or developer to deliver more than the bare minimum.

The roundtable participants all felt the construction industry does not operate as collaboratively as it could. In part, this is due to different roles shifting over time. The role of the architect is seen as having been diminished, while contractors have more power and can overrule design decisions – especially if breaking the specification makes a saving.

A disconnect between specifier and installer

Nor is it always about cost. Sometimes a specification is broken because there is an alternative product that the contractor finds easier to use or better to install. However, breaking specifications for any reason can lead to performance gaps being more likely in finished buildings.

This represents a significant disconnect – a lack of collaboration – between a specifier aiming primarily for performance and a contractor focusing on time and cost. To reduce the performance gap, design needs to inform more of what happens on site. But communication works both ways and design should also learn from, and adapt to, what happens on site.

Somehow that distance needs to be bridged. If it is not done by contractual arrangements, then manufacturers can step up to the plate by innovating and creating new solutions that meet the needs of both parties.

Sheathing boards: a case study

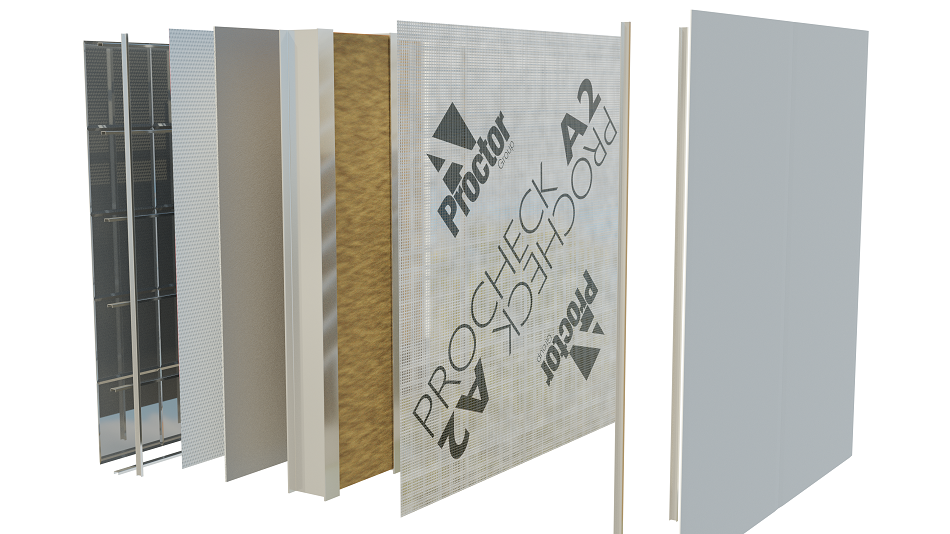

A real-world example of what we’re describing is the specification of sheathing boards for facade build-ups, together with our Wraptite® external air barrier.

Traditional fibre cement sheathing boards offer a variety of benefits, and are frequently specified in conjunction with Wraptite. As a fully self-adhered airtightness membrane which is also vapour permeable, Wraptite allows the airtightness line to be moved to the external face of the structure. In addition, its W1 classification for water holdout means it can provide temporary weather protection to the structure, without the need for tapes and sealants.

However, contractors have come to prefer gypsum-based sheathing boards to fibre cement. They are lighter, and therefore easier to handle, and easier to cut thanks to being score and snap. When contractors break a fibre cement board specification, it’s not uncommon to see the accompanying Wraptite removed at the same time. Gypsum boards offer airtightness and weather protection benefits (with taping and sealing), but not to the same extent that Wraptite offers.

Contractors are choosing a sheathing board that is easier to handle, but which introduces extra processes to the installation – and which may reduce the level of performance intended by the specifier.

Manufacturing products that contractors want to use: Proctor A1 Cement Board

In an effort to support specifiers and contractors, we have launched a new score and snap sheathing board called Proctor A1 Cement Board.

Key to its development was the desire to offer the best possible all-round solution. As a result, Proctor A1 Cement Board combines the benefits of traditional fibre cement boards with the desirable qualities of newer gypsum sheathing boards. Where fibre cement products are heavy and difficult to cut on site, Proctor A1 Cement Board is a cementitious board that is both lightweight and, uniquely, score and snap.

Thanks to its excellent durability, the new sheathing board can be left exposed for longer periods. Taking into account Wraptite’s water holdout performance too, it means structural frames are protected even if project timelines are delayed across installation of the sheathing board and air barrier system.

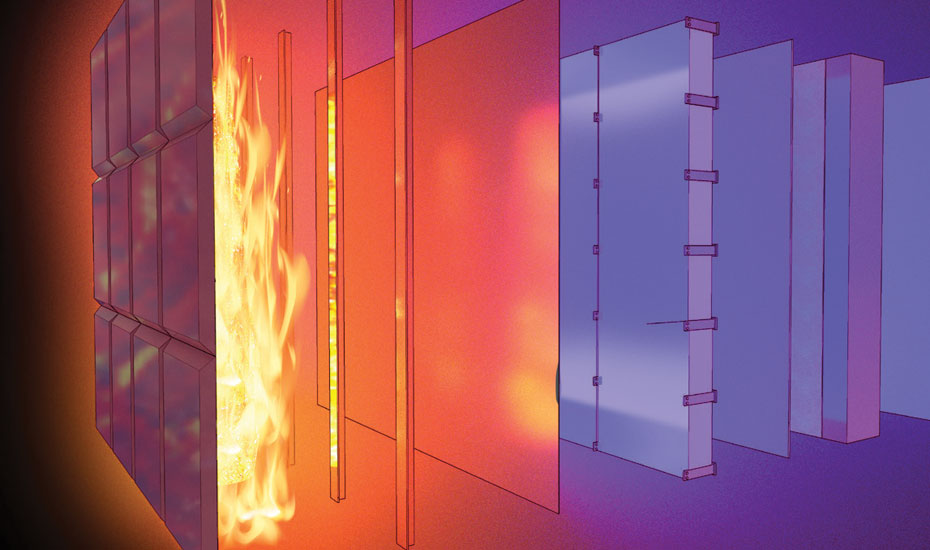

Through-wall fire testing has been carried out on the new sheathing board with Wraptite, ensuring the compatibility of the two. As a cementitious product, Proctor A1 Cement Board is automatically classified as non-combustible. The testing delivered a result of 120 minutes without integrity failure, so customers can feel assured when choosing a fully-adhered, vapour permeable external air barrier.

The combination of Proctor A1 Cement Board and Wraptite is suitable for all projects, but in particular supports compliance with fire safety requirements for relevant buildings and helps specifiers and contractors move more towards a system solution.

Furthermore, Proctor A1 Cement Board is backed up by third-party certification, comprehensive technical support, plus on-site support including all complementary fixings and accessories. In short, it delivers performance while also being contractor-friendly.

See all of our products here: https://proctorgroup.com/all-products

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check