On the roof, David chose Proctor Air as an air permeable, low resistance (APLR) membrane, for use below a traditional slate finish. Maintaining a traditional appearance as part of the conversion work is important to David, given the building’s history of use.

The monopitch roof design made ventilation provision tricky, as David was specific in how he wanted to detail the ridge and keep it secure in the coastal location in Carnoustie. Selecting Proctor Air removed any such concerns, as it provides a uniform flow of air that effectively ventilates the roof space and removes any risk of condensation.

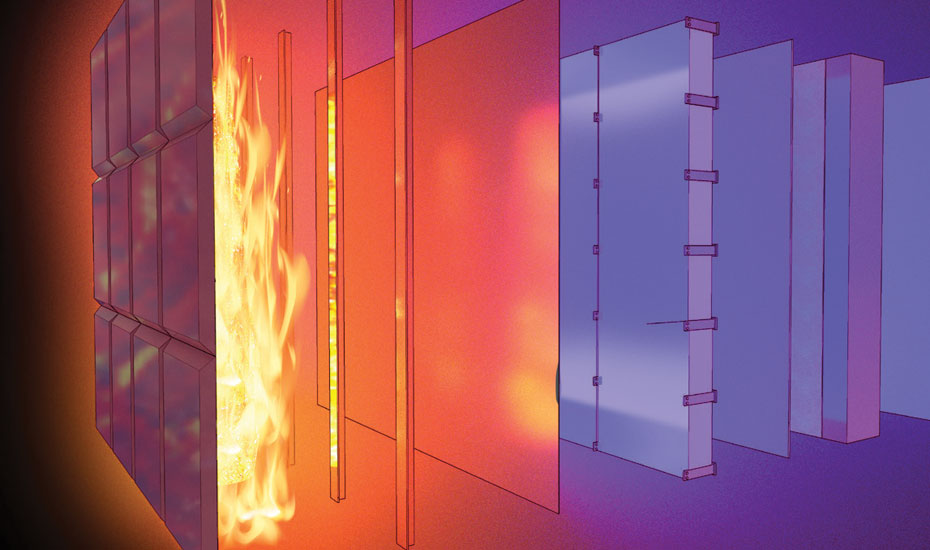

A tile or slate roof finish is the first line of defence against the weather. As water can get into the space below the tile or slate, the chosen underlay must also be capable of resisting water ingress. While not waterproof, Proctor Air has a W1 water resistance, and can be left exposed to UV for up to three months.

“Installing both membranes has all been quite easy and intuitive,” said David, before adding, “as long as it isn’t windy!” Although carrying out as much of the work by himself as possible, he did seek some help in getting the roof membrane installed, acknowledging “that it would be tricky for one person.”

Having an understanding of heat loss and dew points, David was happy to carry out U-value and condensation risk calculations himself. He has been grateful for the support available during the project so far: “I swapped a few emails with the A. Proctor Group technical team to check things were okay,

and Building Control have been really helpful on site as well.”

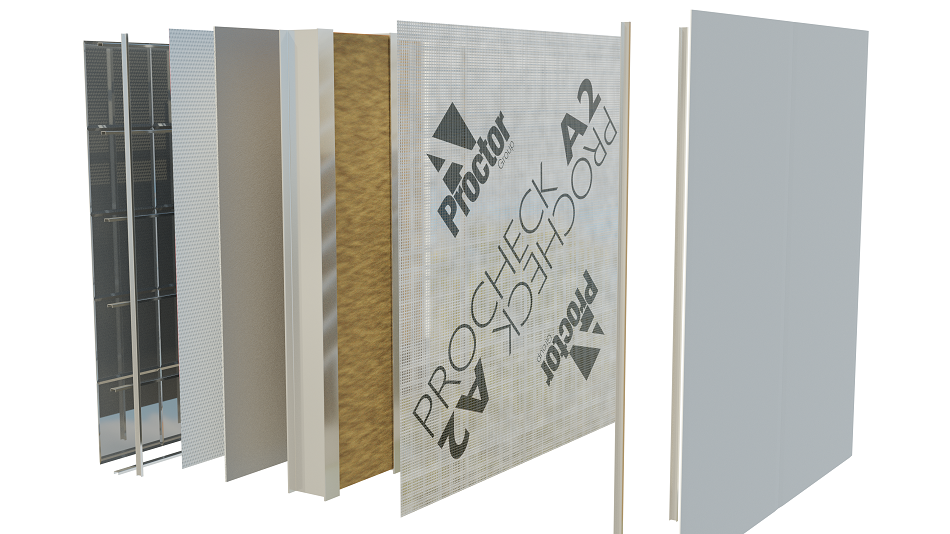

At the time of writing, most of the external works to the boat house are complete. David will move on to the internal works, where he plans to use the company’s Reflectatherm® Plus to the internal side of the timber frame.