How Important Are Window Reveals in An Insulation Strategy?

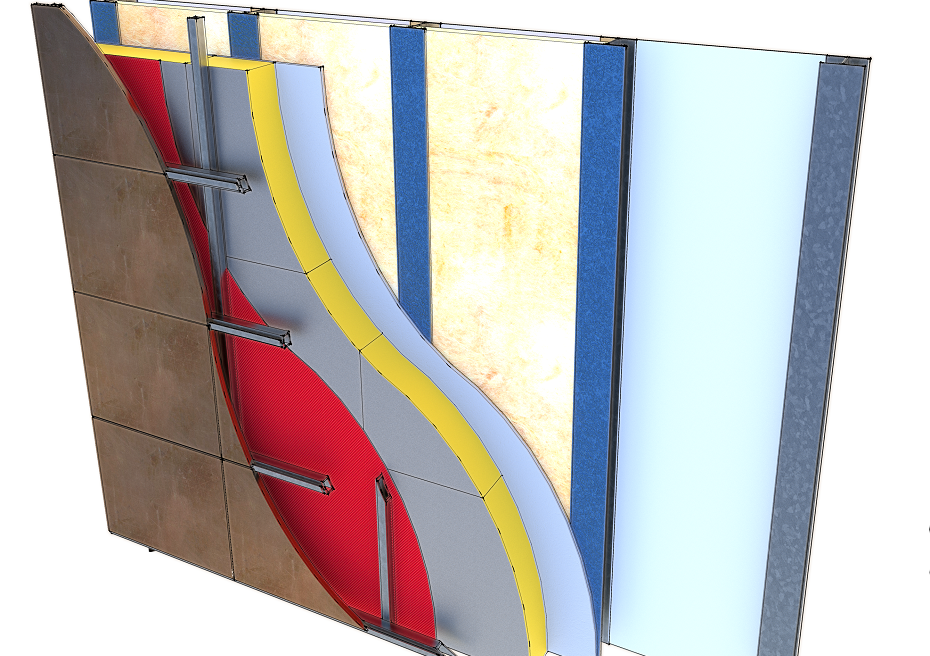

The starting point for thermally efficient building fabric is continuity of the ‘thermal envelope’. The insulation layers in different elements (the floor, walls and roof) should, as far as possible, connect wherever two different elements meet.

In the case of window openings, the windows themselves become part of the thermal envelope.

For new-build construction, windows can be installed in line with the wall insulation to create a direct connection and maintain continuity.

Existing solid wall structures are different. Unless the windows are moved or replaced, applying insulation to either the inside or outside face of the wall leaves the window reveal uninsulated. A solution is needed to connect the wall insulation layer and the window, otherwise the substantial thermal bridge will undermine the thermal performance of the new insulation.

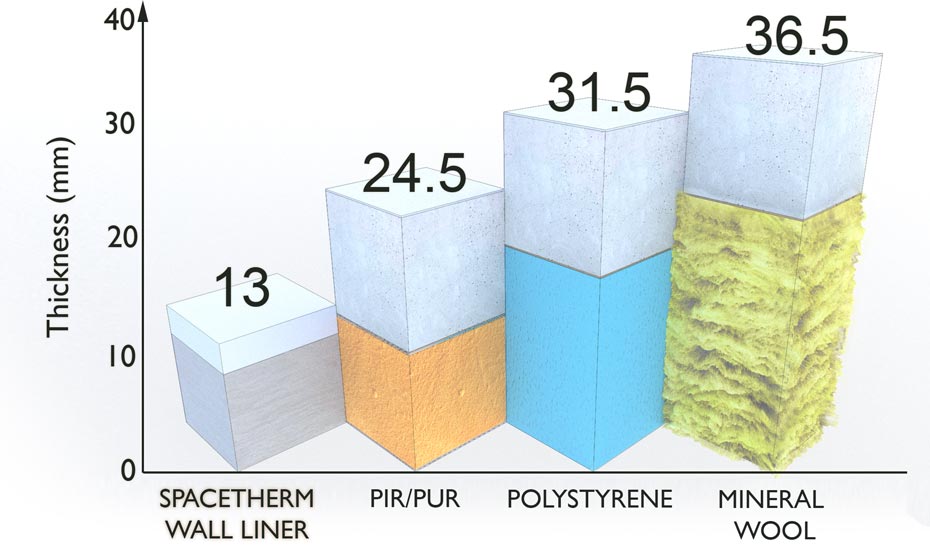

That solution has to be capable of providing sufficient thermal performance to minimise heat loss through the thermal bridge, while also being thin enough to not exceed the width of the window frame.

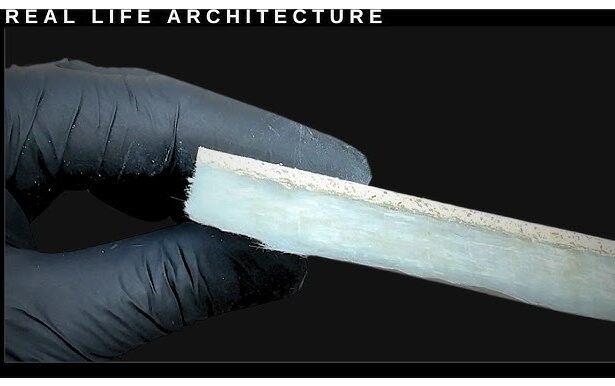

Most common rigid foam insulants are not manufactured at low enough thicknesses to suit window reveal details. An alternative approach is to use an ultra-thin aerogel product, like one from A.Proctor Group’s Spacetherm® range.

What Other Common Thermal Bridging Details Require Similar Attention?

Structural design often takes precedence over design for thermal efficiency, leading to many of the most common thermal bridges.

Thermal insulation products are not structural. They cannot bear loads imposed on them, so structural elements frequently have to interrupt insulation layers. Examples include the top of an external wall supporting the roof, or an intermediate floor slab or party wall interacting with an external wall.

A designer might assume they have left enough space to accommodate steel beams or columns, only for the engineer to specify larger sections. The beams or columns then protrude into the insulation layer, interrupting its continuity and making the insulation harder to install.

Improvising solutions on site is one of the biggest risks to insulation performance, so the design stage of projects is the best time to address potential thermal bridges.

Building regulations guidance for new construction, like Approved Document L, supports this. However, it only says that thermal bridging should be “reasonably limited” and complex detailing should be avoided “wherever possible”. Even with the best intention from designers and specifiers, this can be easier said than done.

Thanks to their combination of performance characteristics, aerogel products have applications in both existing and new buildings, and can help to address thermal bridges. Like any product, though, they need to be specified and installed correctly – so it helps to first analyse details to ensure a solution is appropriate.

How Is Heat Loss and Condensation Risk at Thermal Bridges Analysed?

Thermally modelling junction details and thermal bridges is established practice in construction. However, one issue with calculating psi value heat losses is there being no ‘correct’ value to achieve. Building regulations mandate maximum U-values, but there is no similar threshold for psi values.

Designers and specifiers who obtain psi values can’t be completely sure whether the performance achieved will actually help to deliver a healthy building.

To support the correct specification of aerogel solutions at thermal bridges, the A.Proctor Group has launched a thermal bridging calculation service. It goes a step further than calculating heat loss alone. The output also includes a surface temperature factor, or fRSI, which indicates the internal surface temperature at the junction detail.

The fRSI predicts the likelihood of condensation and mould growth occurring. In residential buildings, a thermal bridge needs to achieve an fRSI of 0.75 or greater to ensure condensation will not occur.

This clearly defined target is much more helpful. If initial modelling shows a thermal bridge to be a condensation risk, we can rerun the simulation with a thin layer of Spacetherm insulation. Designers and specifiers can be confident their detail is then free of condensation risk, alongside improved thermal performance from a continuous insulation layer.

Our thermal bridging calculation service fits seamlessly alongside our other technical support services, including condensation risk analysis using the Glaser method or WUFI®, allowing us to determine moisture content throughout building elements.

Find out more below:

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check