What is the thermal conductivity of aerogel and low lambda foam insulants?

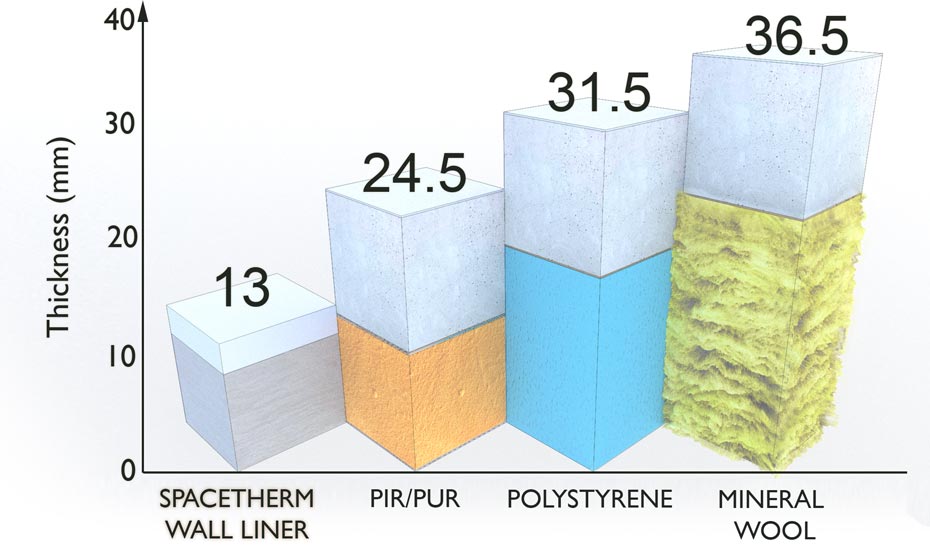

- Typical thermal conductivities range from 0.020 W/mK for aerogel and phenolic insulation, to 0.022 W/mK for a typical PIR foam board.

- This range is lower (and therefore more thermally efficient) than most other commonly-used insulation types. The similarity in performance means all of the products offer a similar thermal benefit for similar thicknesses.

- Precise lambda values can vary by manufacturer. For example, Proctor Group’s aerogel blanket product, Spacetherm® A1, has a thermal conductivity of 0.0195 W/mK.

What are the advantages of this thermal efficiency?

The low lambda of rigid insulation products like PIR and phenolic allows better U-values to be achieved in constructions for which the products are typically offered, including floors, walls, and roofs.

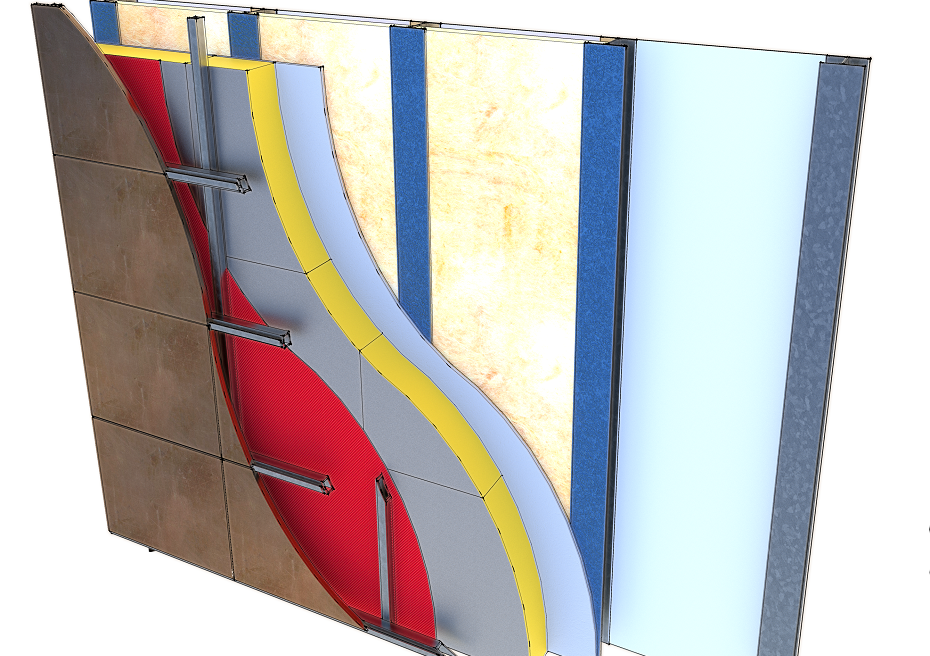

However, in solid wall applications, an air gap is often required due to the fact that the thermal performance is detrimentally affected by being installed to a potentially more moisture sensitive substrate. In addition, the lowest U-values offered by rigid boards often depend on the insulation’s foil facing delivering a low emissivity benefit in an adjacent air space.

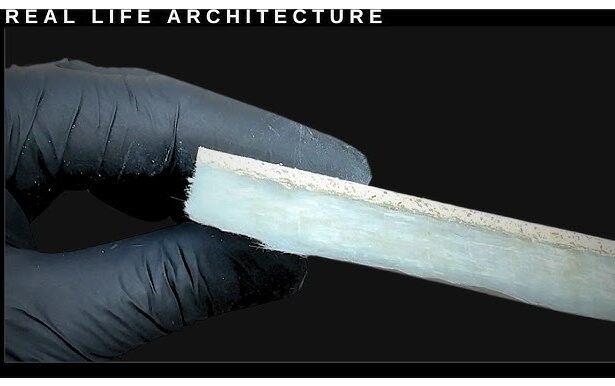

Aerogel insulation is inherently hydrophobic, meaning it is completely inert to the effects of moisture. This means it can be fixed directly to solid, and cavity, walls without compromising thermal performance or damaging the insulation. And because aerogel has no foil facing to provide an enhanced low emissivity cavity, no air space is required for the insulation to face into.

The unique composition of aerogel means it can help to deliver thermal efficiency in space-critical areas where ‘conventional’ insulation products are simply too thick. The material is generally manufactured in 5-10mm thicknesses, which can be layered to suit the required thermal performance. These thin layers make insulation possible in applications where foam boards cannot be supplied at the thickness required.

Using aerogel, the thermal performance of ventilated facades can be enhanced generally, as can areas of thermal bridge detailing such as window reveals and steel beams.

Are aerogel’s moisture characteristics important for solid wall constructions?

Moisture management in buildings is critical to the longevity of the building fabric and achieving the intended performance from building elements. Insulation materials therefore have to be selected not just for their thermal performance, but also to support good moisture management.

In new build, timber, steel, and concrete framed buildings, as well as more traditional cavity wall constructions, the constructions are less moisture sensitive. This allows greater flexibility in the type and physical properties of the insulation. Foam insulants are more than suitable for use as the constructions benefit from a low permeability insulation to reduce the amount of vapour that can pass through the construction.

This is not the case with historic, solid brick and stone buildings, however. In historic solid masonry walls, we can have a lot of influence on the way moisture moves due to both external and internal conditions.

Solid walls are heavily influenced by driving rain on the outside, often allowing quite a bit of natural moisture penetration. The effect of this is heavily tempered by the internal heat driving or drying the moisture out of the wall. This allows these walls to reach a seasonal equilibrium that has allowed them to stand, in some cases, for several hundred years. Installing insulation and other energy efficiency measures affects the building physics of the wall.

For example, adding insulation can keep the interior warmer and cut fuel costs, but it can also mean the walls are now significantly colder than they have ever been due to not getting any heat to them to help drive out the moisture. This can result in interstitial condensation or moisture accumulating in the stone or brick like a reservoir, leading to structural implications which could quickly escalate.

Using vapour permeable aerogel internally can help the wall to dry in both directions, internally as well as externally. Impermeable foams and membranes will limit drying to out only, meaning no moisture buffering during the hotter months. Balancing the thickness of vapour permeable aerogel means you can get a good level of thermal comfort without building in any moisture or drying out issues. Our technical team has extensive knowledge of modeling these types of construction and can provide tailored advice depending on the extent of refurbishment being aimed for.

To summarise, traditional buildings featuring solid wall constructions must be treated correctly when looking to install an internal wall insulation system. While every building behaves differently, it can broadly be said that there are times when a solid wall needs to dry to the inside of the building.

This puts the onus on the building fabric to be breathable and allow the passage of moisture vapour. Otherwise, moisture remains trapped in the masonry and can lead to mould and deterioration of the wall build-up.

The vapour permeability of aerogel is therefore a highly desirable performance characteristic for retrofitting traditional buildings, allowing it to be installed directly onto the wall. The impermeability of PIR and phenolic insulation requires the foam boards to be installed with an air space between them and the masonry – adding to the overall depth of the insulation system and eating into more of the existing floor space.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check