Challenges

From a technical standpoint, historic façades that are destined to become part of a modern external envelope must be updated to meet current building standards in terms of airtightness and thermal performance. As the point of preserving a façade is to maintain its external appearance, improvements like air barriers and insulation must be added to the façade’s internal face. Considerations for how new materials (e.g.: non-breathable rigid insulation) will interact with retained materials (e.g.: breathable stone façade), and any thermal bridging resulting from the new structure being physically attached to the old, must be taken into account to avoid interstitial condensation risk potential.

Material selection must balance performance with practicality as all new materials installed on the inside of a façade will determine how much internal space is left over. For example, while the vapour permeability of mineral wool insulation may seem a good match for historic breathable façades, the bulkiness of the material may encroach so much into internal spaces as to make them unfit for purpose. Upgrading a façade from the inside may be further complicated if a building’s frontage does not have sufficient space or local permissions for the temporary support structure to be erected externally, meaning contractors will have to work in a web of constricted space formed by temporary steel framing built within the construction site itself.

Solution

Clearly, the interface between what is replaced and what is retained is of fundamental importance to addressing the challenges of air leakage and thermal bridging in façade retention projects. Wraptherm®, a composite material combining the vapour-permeable properties of Wraptite® external air barrier with ultra-thin Spacetherm® aerogel insulation, offers a simple and compelling solution.

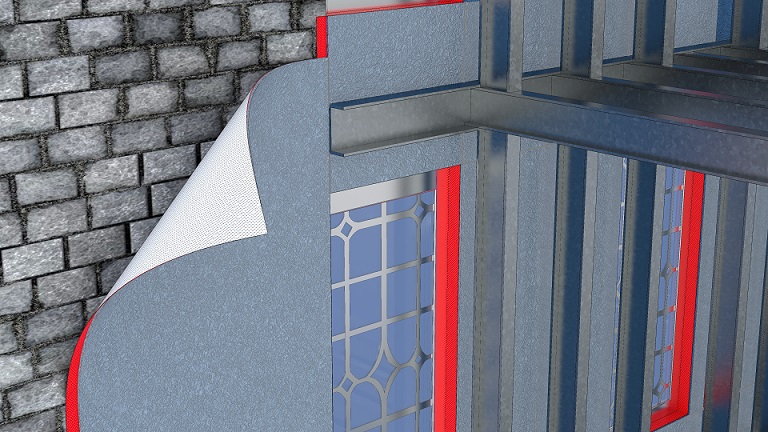

Wraptherm is installed to the inside face of retained façades via its self-adhering backing and is compatible with almost any substrate. Installation process is simple and straight-forward, and the resulting airtight seal limits the heat loss associated with air leakage through gaps and cracks in the façade. As both components of Wraptherm are vapour-permeable, the material helps to offset any negative effects that upgrades may have on the natural movement of water vapour through the building envelope. As well as protecting the existing building fabric, Wraptherm’s hydrophobic properties provide a secondary barrier against water ingress by tightly sealing door and window penetrations. Finally, the 10mm layer of aerogel insulation limits cold bridging by providing an effective thermal break between the cold external façade and the new warm internal structure.

Wraptherm’s combination of airtightness and excellent thermal performance benefits internal spaces by reducing the amount of additional insulation required to meet standard, reduces interstitial condensation risk by providing a continuous thermal break across the façade interface, and by potentially making other wall elements like the vapour control layer unnecessary. The installation method and manageable format speeds up the installation process and makes working in confined areas easier.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check