What Design Approaches Should Be Adopted for Retrofit?

This seemingly simple question prompted a lot of debate, and the round table contributors were united in their answer: “it depends”.

So many factors affect how existing buildings can be retrofitted: the age and condition of the fabric; planning restrictions; and whether work can be carried out all at once or in phases.

A lot of effort has gone into building up knowledge about typical building types and construction methods from different periods. Sometimes, however, certain properties are simply very hard to deal with and retrofit effectively, however much you might know about them.

Taking time to carry out surveys and tests on an existing building is vital to establish a performance baseline, from which improvements can then be planned, installed and quantified. Adaptability is also necessary, as work on buildings (especially older buildings) starts to uncover unexpected construction techniques that have the potential to impact on plans and their intended performance.

Retrofit: Ambition vs Reality

Retrofitting existing housing stock is a challenge, and one that has only been made harder as a result of changes in government policy.

In 2015, the introduction of zero carbon homes planned for 2016 was scrapped. Now, some nine years later, the Future Homes Standard intended for 2025 aims to deliver homes that are ‘zero carbon ready’, subject to the decarbonisation of grid electricity.

In the intervening period, it is estimated that 1.5 million new homes have been built that will require retrofitting in order to help the country achieve net zero. Yet it is only in the last few years, spurred by significant rises in energy prices, that more homeowners have become aware of the energy performance of their properties.

While purchasers of new homes can select from a range of options for internal finishes, they do not have the option to request better levels of insulation or airtightness. Theoretically, this soon shouldn’t matter if the Future Homes Standard delivers what it promises.

For those purchasing an existing dwelling – whatever its age and condition – the option is available to carry out appropriate retrofit measures. There is some real momentum in the UK retrofit market, but it will never be the case that one single whole-house solution can be applied to the vast array of homes that make up the country’s housing stock.

Available budget inevitably dictates what level of ambition can be realised in a retrofit project. When only 10% of people have more than £5000 in savings, how can they afford larger-scale interventions like heat pumps and external wall insulation?

However robustly designed a retrofit scheme is, if the money isn’t available to carry it out then the work risks being done poorly or left incomplete – with possible negative consequences for the building fabric, rather than improving it.

Creating the Solutions to Improve Retrofit Outcomes

Given the potential outcomes in terms of occupant health and comfort, there are times where it might be better to do no retrofit rather than attempt energy efficiency improvements and do them badly.

At the same time, we also can’t risk putting people off the idea of retrofitting their properties. Unfortunately, the cost and hassle of deep retrofit can do just that. While gas and electricity bills are likely to remain relatively high, the realisation of what is required to help reduce them often leads many homeowners to scale back their ambitions – or abandon them entirely.

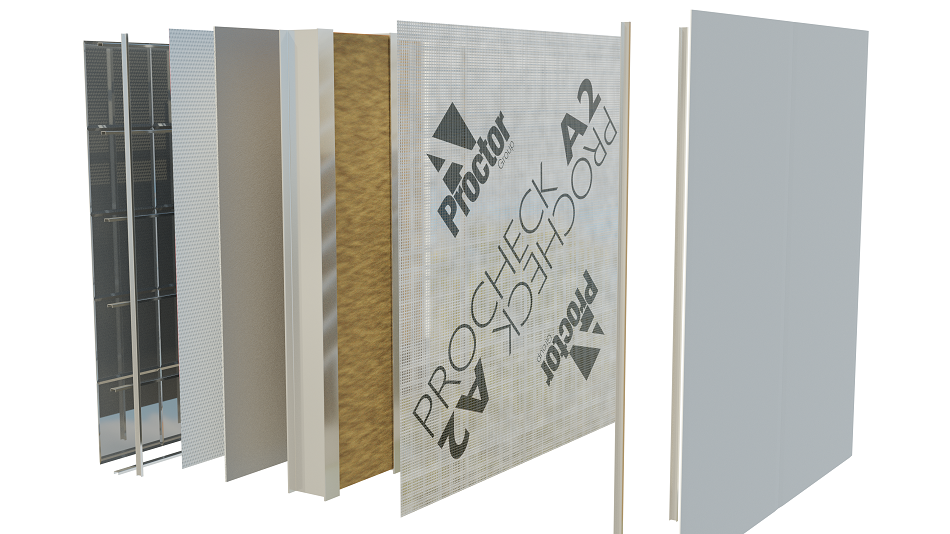

Product manufacturers can play a part by developing robust solutions that contribute to building performance improvements, without restricting potential retrofit measures that might be carried out at a later date.

Proctor Air, the pitched roof underlay from A.Proctor Group, is one such product. It is an air permeable low-resistance (APLR) underlay that allows the passage of both air and moisture vapour from the roof space. Condensation risk in the roof space is therefore removed.

As such, it doesn’t matter whether there is a VCL in the existing ceilings below the roof space. It also doesn’t matter whether the existing roof space ventilation is adequate or not. Proctor Air provides a more uniform flow of air than normal vents, without any concerns over loft insulation upgrades causing eaves ventilation to become blocked.

Using Proctor Air, a routine replacement of the roofing system can be carried out in the knowledge that, even if insulation upgrades can’t be carried out at the same time, the building and its occupants will benefit from an overall improvement in roof performance. The roof space enjoys more effective moisture control, without ruling out potential retrofit measures in the future.

Explore this topic further by viewing the full round table event on the A. Proctor Group YouTube channel.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check