How can we help the roofs of dwellings to perform better while making life easier for specifiers, installers and homeowners?

What factors affect the amount of ventilation required in a roof space?

First, it helps to understand why the topic of roof ventilation can get so complex. The need for eaves ventilation alone, or a combination of eaves and ridge ventilation working together, depends on a number of variables.

Is the roof underlay a traditional high-resistance (HR) membrane, like bitumen felt, which doesn’t allow the passage of vapour or air? Is it a more modern low-resistance (LR) membrane – and, if so, is it airtight? If it is airtight then it allows vapour diffusion but doesn’t have the additional benefit of air passing through to enhance moisture removal.

Having determined the type of underlay, other factors start to come into play. The width of the building – and therefore the distance across the roof space – is a consideration for roofs with an HR underlay. The pitch of the roof can also affect whether adequate airflow is achieved.

The performance of airtight vapour permeable (LR) underlays, and the extent of the ventilation required, depends whether the ceiling of the top storey is well-sealed or not. Even if a ceiling is well-sealed when first built, home improvements and renovation works carried out later could change that.

Whether eaves ventilation, ridge ventilation, or a combination of both is required, there is no single solution in terms of the size of ventilation openings that must be installed.

What do we mean by a ‘complex’ roof space?

Not every roof space matches the simple, unobstructed, dual-pitch roof that usually illustrates ventilation guidance. Any variation from that is what we’re choosing to term a more ‘complex’ roof.

As the Loft Conversion Project Guide describes , potential restrictions at eaves can affect ventilation provision. This is a particular issue with the increasing insulation thicknesses expected in roof spaces.

Changes in roof slope (i.e., valleys and hips) and changes in construction details (e.g., a junction between a pitched roof and a flat roof) all make clear roof spaces more difficult to achieve.

And obstructions such as dormers, roof windows, compartment walls, fire barriers or changes in pitch all create separate ventilation voids in the roof slope. Any complicated detailing makes it necessary to add more ventilation openings.

Any of the situations described above can change the way air flows within a roof space. The diligent installation of ventilation openings, all in the right place and all of the correct size, is not enough to guarantee avoiding ‘dead zones’ within the roof space. In such areas, reduced air flow means moisture removal is not consistent across the whole roof space.

Proctor Air®: a solution to achieve consistent moisture removal

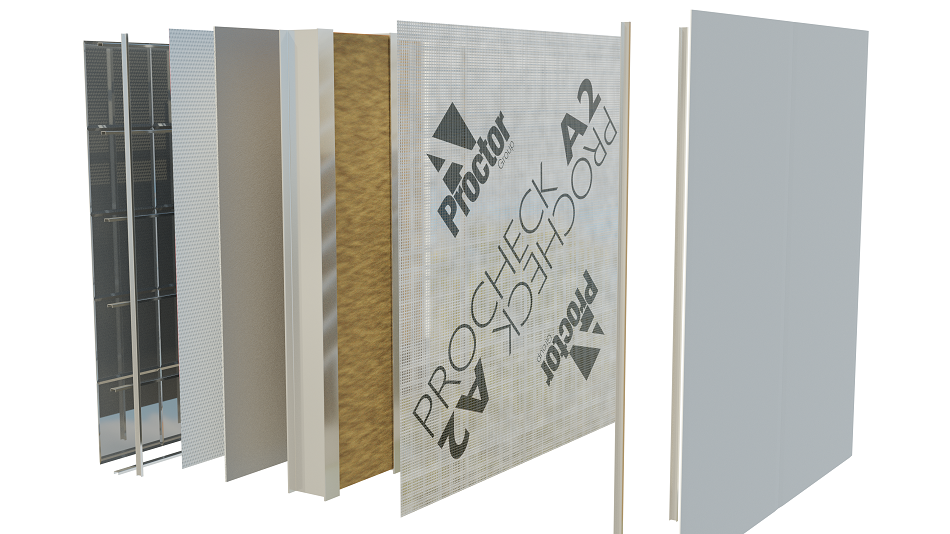

A. Proctor Group’s new pitched roof underlay, Proctor Air, is the perfect solution for roofs of all types, including complex roofs. As an air permeable LR underlay, no VCL is required in the ceiling and no ventilation measures are required in the cold roof space.

Proctor Air permits the passage of both air and moisture vapour, providing a uniform flow of air compared to normal vents. Condensation risk in the roof space is therefore removed.

Among other benefits, Proctor Air’s water resistance has also been tested and meets the threshold of over 1m of water holdout recommended in the NFRC’s Technical Bulletin TB06.

A. Proctor Group is a 4th generation family business with a history of technical innovation, promoting good practice, and developing products that roofing contractors want to use. We have applied this wealth of experience to creating the next generation of air permeable LR membrane.

All of this is backed by our 15-year warranty, offering peace of mind even in the face of an uncertain future climate.

For more information visit: https://proctorgroup.com/products/proctor-air

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check