How to Provide Ground Gas Protection

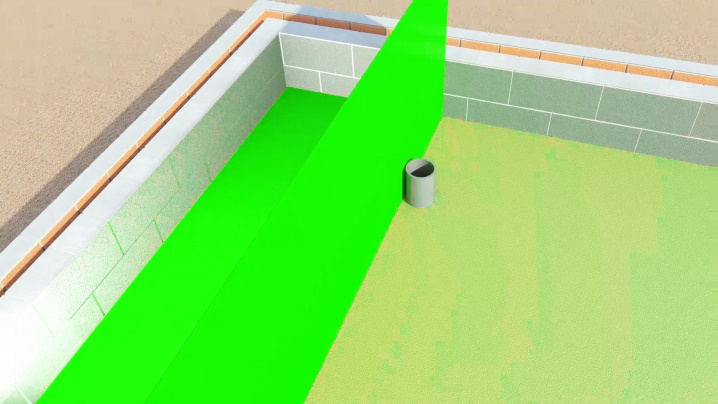

The development of greenfield sites alone is not the answer; the remediation of suitable brownfield sites must play a role in helping UK builders achieve the government’s ambitious targets for new housing provision. To this end, a number of initiatives have been launched to help streamline the brownfield remediation process. An understanding of common soil contaminants, the process of brownfield site classification, and the components that make up a comprehensive ground gas protection system is essential for new construction to be built safely over brownfield sites.

The purpose of ground gas protection is to prevent hazardous gases and contaminants present on brownfield sites from entering buildings and harming occupants. Ground gas protection is determined by methodologies set out in advisory documents such as BS8454:2015 and CIRIA 748, 735 and 716, and through site investigations that measure the type and quantity of ground gas and soil contaminants present. Engineers then classify the site by comparing the level of risk to humans to the site’s zoning and the type of construction proposed, with specific attention paid to floor, slab and substructure design. The result is a numerical ‘point’ score that the ground gas protection system must achieve in order to satisfy British safety standards for that site.

The A. Proctor Group offers specialist knowledge and design advice for ground gas protection solutions in accordance with the most up-to-date guidance documents and with a value-engineered approach. Our wide range of proprietary gas membranes, ventilation systems and accessories are easily customised to meet the requirements of brownfield sites.

Protech GM Super Proprietary Gas Membrane is a 1600g reinforced LDPE membrane which incorporates an aluminium foil layer for maximum protection against Radon, Carbon Dioxide and Methane.

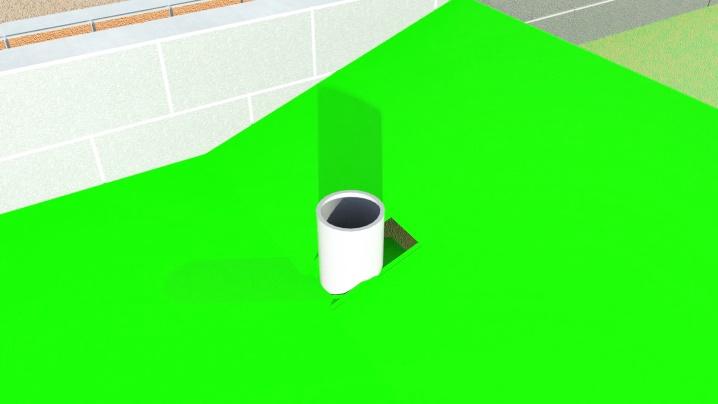

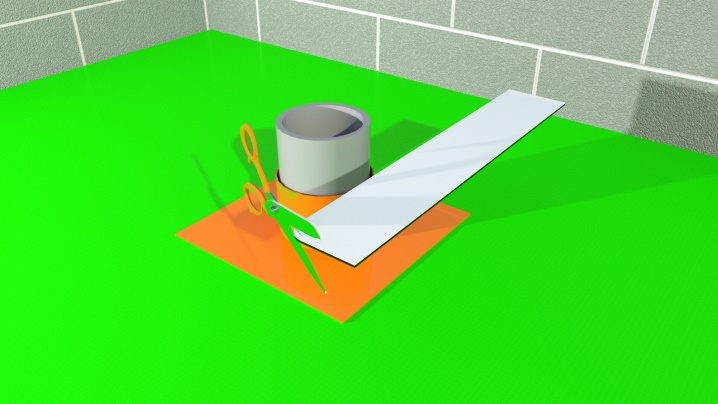

1. Lay membrane over 50mm sand blinding or Protech GM Protection Fleece to prevent punctures. Fold edge of membrane up adjacent to pipe.

2. Using a Stanley knife, make a vertical cut long enough to slip the membrane over the top of the pipe.

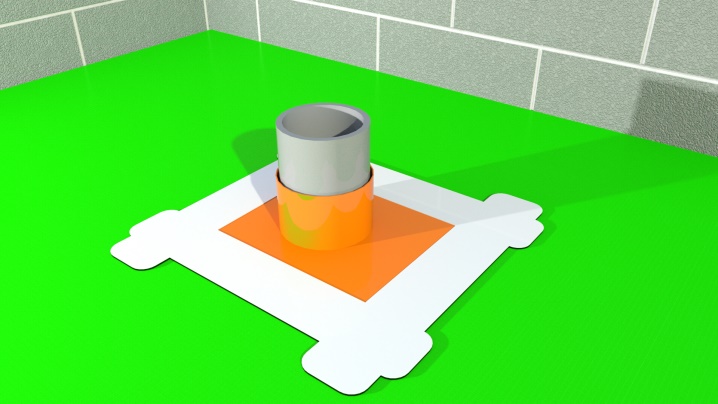

3. Cut edges to allow the membrane to sit flat. Ensure cuts are no larger than necessary.

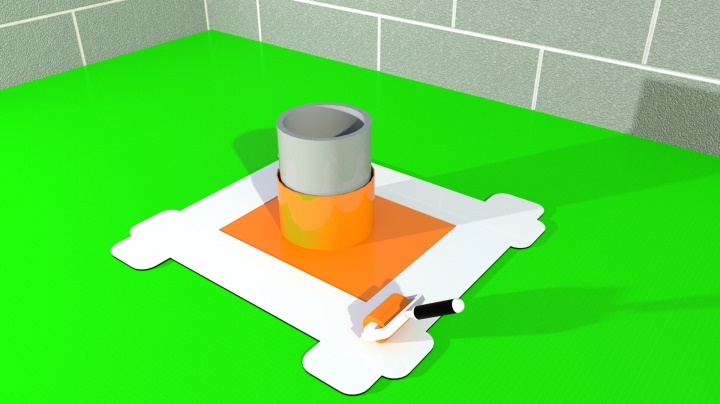

4. Slide Protech GM Top Hat down over the pipe, rotating as needed to fully cover the cuts in the membrane.

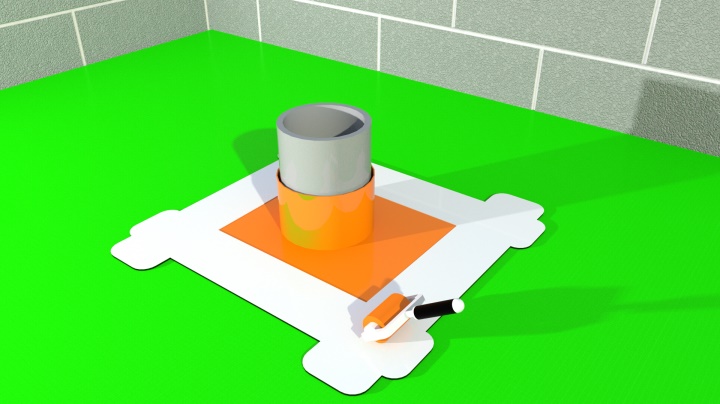

5. Apply strips of Protech GM Flashing Tape to the base of the Top Hat. Rounding off the Tape’s corners will help prevent the strips from lifting.

6. Press Protech GM Flashing Tape firmly into place using a wide roller.

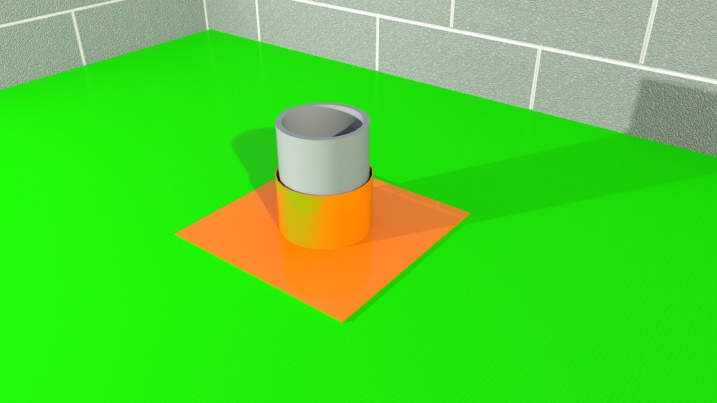

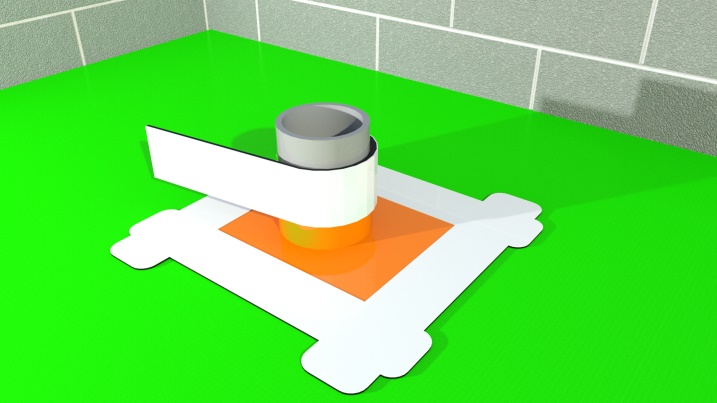

7. Wrap Protech GM Flashing Tape around the top edge of the Top Hat and roll firmly into place. Ensure Flashing Tape is smooth with no wrinkles.