The house design is a load-bearing Lightweight Steel Frame Construction. The steel frame system’s exterior finish is formed of a 12mm Y-Wall Sheathing Board, the Wraptite Airtight Breather Membrane, and a 150mm Sto EPS Insulated Render System.

The U-Value and condensation risk calculations carried out by the A. Proctor Group on the proposed through wall build-up confirmed no risk of condensation.

Because the house is a self-build project and the external finish was not critical to the overall programme, the membrane provided both a damage resistant air barrier layer and effective secondary weather protection in one installation process, to allow internal trades to proceed earlier. In addition, the self-adhesive application of Wraptite enables it to be left exposed for up to 120 days during construction.

On the performance of Wraptite on the project, Mark Skinnader commented, “The experience with Wraptite has been excellent. The material is extremely high quality and has provided an excellent weathertight seal to the building envelope. In addition, the selfadhesive nature of Wraptite makes the installation much quicker and more efficient. Waste was minimal, and offcuts could be re-used. The A. Proctor Group also provided Wraptite Liquid Flashing for sealing around windows, another excellent product. I am now actively looking at Wraptite on several large scale projects.”

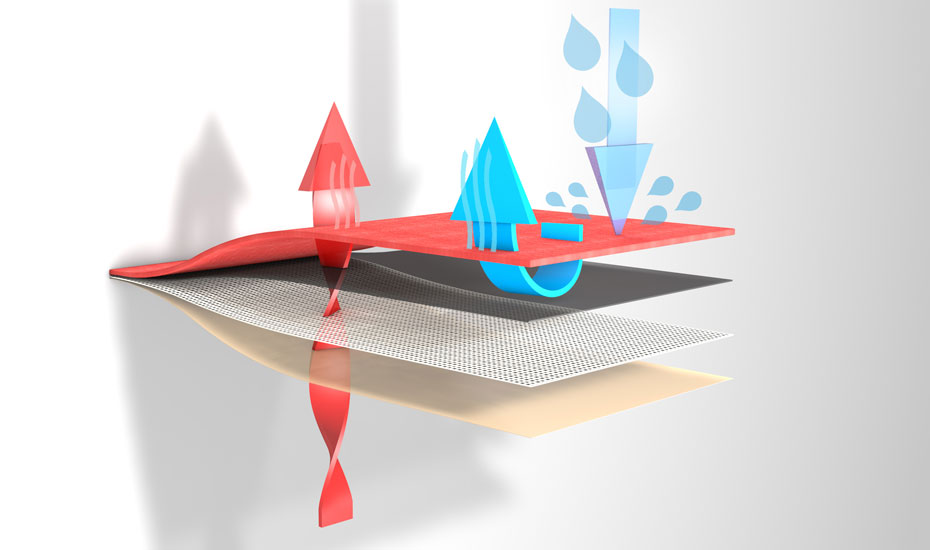

The Wraptite system is the only self-adhering vapour permeable air barrier certified by the BBA. It combines the critical properties of vapour permeability and airtightness in one self-adhering membrane. As a result, it provides high vapour permeability in a continuously sealed, airtight membrane, saving time and cost.

The high vapour permeability of the Wraptite air barrier allows the substrate beneath to dry quickly and moisture vapour to escape and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion.