Addressing the performance gap: design

At its simplest, the performance gap is a fundamental disconnect between what is designed and specified, and what is actually built on site. That disconnect also creates gaps in knowledge. Does a designer or specifier know that what they intended is what will get built? Does the building owner or purchaser know what the original design was, and how the as-built property compares?

In many cases, the answer to both questions is no.

If you buy a 200-year-old home, you don’t expect to know everything that has been changed in that time (it’s part of what makes retrofit so difficult). Yet the industry is building new homes today that will still need retrofitting at some point, and which risk leaving their owners similarly in the dark.

Improving the flow of information from the design office to the building site, using technology and digital tools, can reduce the knowledge gap – and, with it, the performance gap.

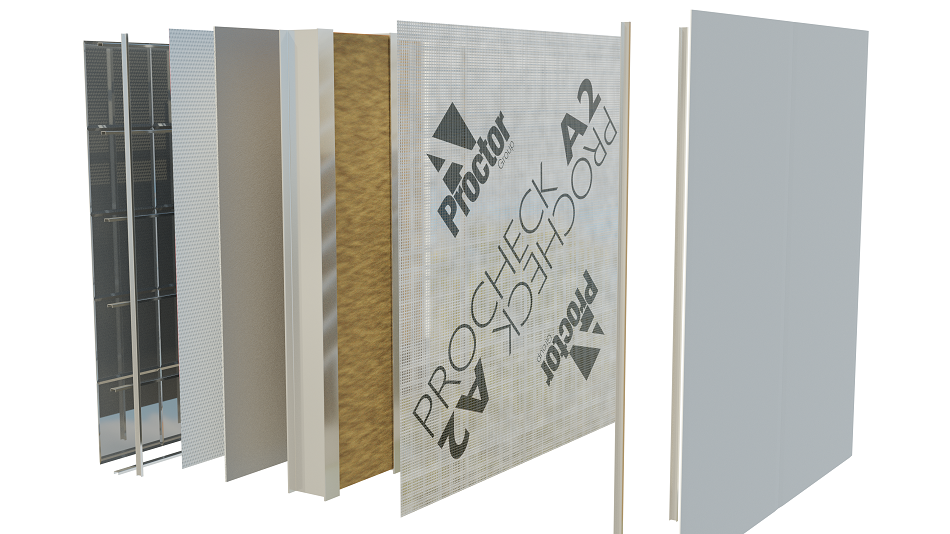

The industry has the means to trace products and components through the whole life cycle, from manufacture, through installation, to reuse, recycling and the circular economy. By incorporating some of that traceability into building designs, it makes it more likely that design intent is realised.

Addressing the performance gap: build

Communication works both ways, and design should also learn from, and adapt to, what happens on site. When contractors feed back on what works, what doesn’t, and what products they like to use, it opens up the possibility to make specifications accordingly.

(See our Proctor Promotes Good Practice article from last month, about the launch of our Proctor A1 Cement Board, as an example of that in action.)

With better communication comes a greater possibility of getting things right first time. Otherwise, remedial works to correct mistakes in insulation, airtightness, thermal bridging and/or ventilation systems are so invasive and onerous that there’s a high likelihood they simply won’t get done.

Unfortunately, whether it is accurate or not, the perception of housebuilding is one of an industry that is better at fixing things than getting them right in the first place. This isn’t compatible with getting high-performance, low-carbon homes right from the outset.

Getting things right first time is a hallmark of the Passivhaus standard, and it has a track record of delivering buildings that perform in line with expectations. Its success is built on communication: contractors, who often don’t have experience of the standard, face a steep learning curve – but many appreciate the opportunity to learn new skills, perform their role better, and carry the learning with them to future projects.

Addressing the performance gap: test

Changing how we design and build can also be informed by measuring the performance of buildings in use. However, the construction industry spends a lot of money on compliance software and certification, and comparatively little on performance software and monitoring.

There are a variety of reasons for this. If a development is signed of as compliant with building regulations, often that is seen as sufficient. Or people might not know that monitoring exists or can be done. Or, if budgets are stretched, then post-occupancy services are likely to be the first additional cost to be ruled out.

It is possible to do in-situ U-value measurements at a single point. But test multiple points of, say, a wall and you will likely get slightly different answers in each place. Compare each result to the U-value on paper and there is a risk of an endless snagging list that can never be satisfactorily resolved.

Instead, whole-building tests for the likes of airtightness and heat coefficient are preferable, because they give an overall picture.

In time, industry aims to feed results from specialist testing into a form of repeatable robust detailing that could deliver buildings which wouldn’t then need to be tested – bringing us full circle to how we address knowledge gaps.

View the performance gap round table:

https://proctorgroup.com/webinars/round-table-design-build-test-closing-the-performance-gap

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check