Keira Proctor (KP): What are breathable membranes?

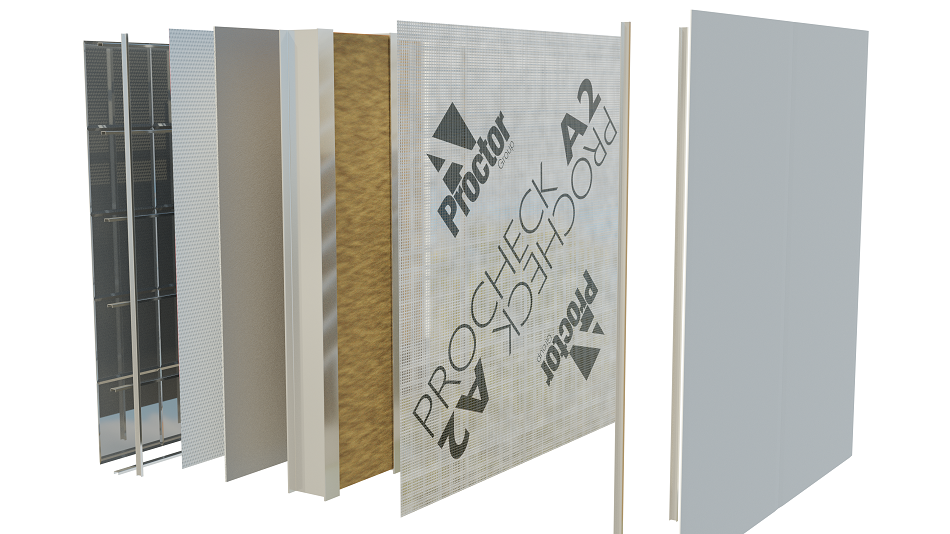

Sue Menmuir (SM): Simply, a breather membrane allows vapour to pass through it from inside to outside. They’re known as low resistance (LR) underlays, and the basic principle is to allow vapour to escape and reduce condensation risk. Membranes provide the roof with secondary weather protection (the roof covering is always the primary protection), so they are water resistant – not waterproof.

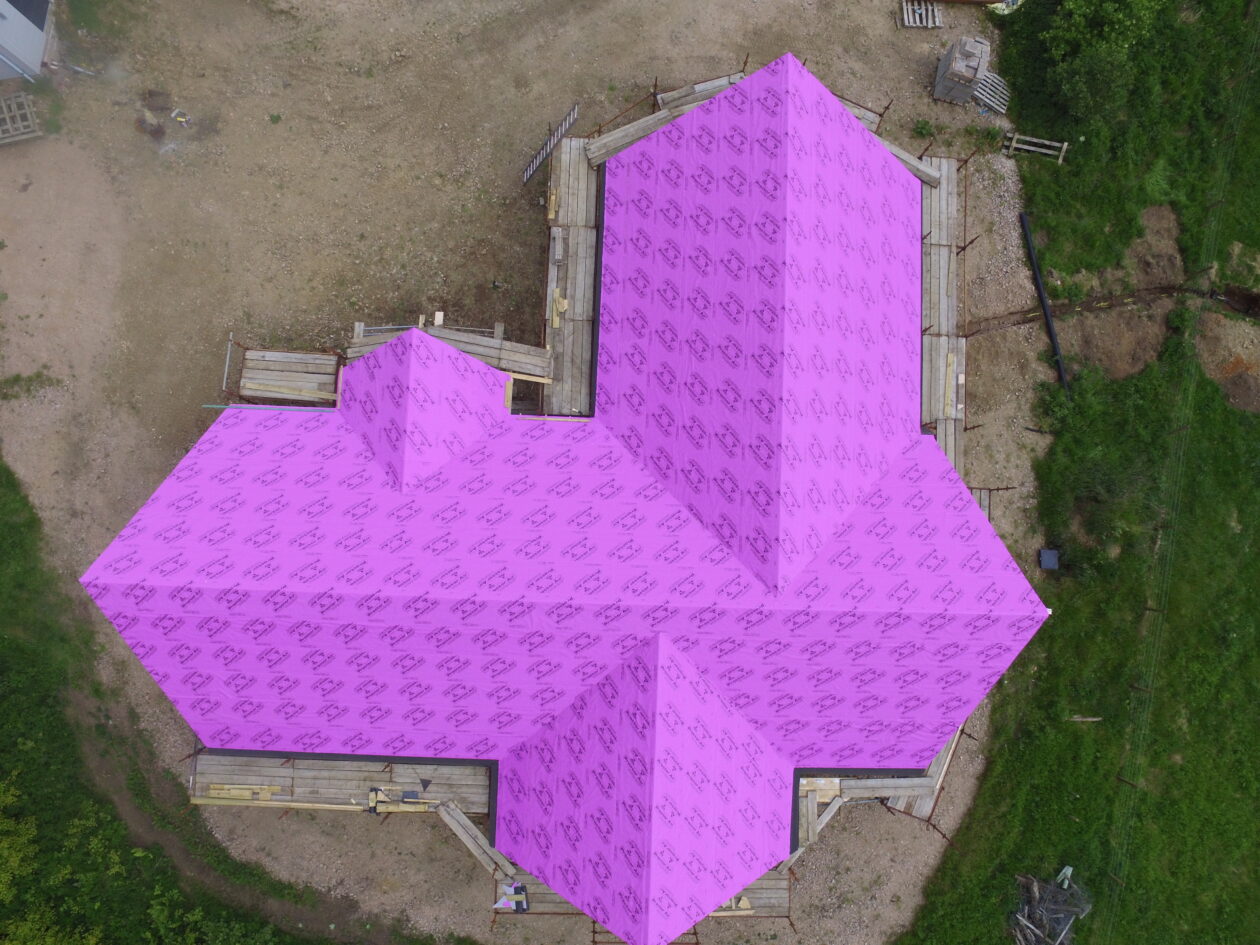

Will Jones (WJ): Membranes have done their job so well in the last thirty years that it’s almost a negative. They’re being left exposed for long periods and it’s considered okay because they haven’t let water in. More wet weather generally, and more intense storms, leads to a higher risk of membranes failing. There’s a need to evaluate and understand why and how these issues can occur.

KP: I see a project every day where there’s a Proctor membrane and it’s probably been exposed for four years! Only a very small part of the roof, and it has decent pitch for water run-off, but it makes you wonder.

WJ: Depending on how sheltered that part of the roof is, you might get away with that.

KP: Does roof pitch come into membrane testing?

SM: No, but it does make a difference in reality. The steeper the pitch the quicker water will run off it. On a shallower pitch there’s more risk of water sitting on the membrane.

WJ: Weather can affect a membrane overnight, which people don’t expect if they’ve left one exposed for several months with no apparent issue. There’s a difference between leaving a membrane exposed during summer compared to during winter or in a storm. It requires common sense rather than assuming they’re fine in any situation.

KP: What industry testing standards are there?

SM: We typically advise a maximum exposure time of three months. That’s normally to do with protection from UV exposure. Beyond three months, UV exposure can degrade the membrane and start to affect its properties.

Our internal testing has shown that between six and nine months of exposure can cause a membrane’s BS EN 13589-1 water penetration classification to drop from W1 to W2. For roofs you need W1.

A lot of membranes will pass that test but not offer the same hydrostatic head. The A.Proctor Group also carries out hydrostatic head testing on membrane, which is a more realistic test compared to W1 test. We aim to be over 1m for hydrostatic head, and the combination of the two gives a realistic overview of the membrane’s performance.

WJ: Do you only have to do the water penetration test once to get the W1 classification? You don’t have to leave it exposed?

SM: No, it’s just the membrane as received.

WJ: That’s important to understand. If you did have to age the membrane and test it, that would give a more realistic view.

KP: What best practices should be adopted during installation to minimise risk of concerns? Presumably, get your tiles on as quickly as possible!

SM: Leave it exposed for the least possible time, and not just because of UV exposure. Proctor Air®, for example, is air permeable so you don’t tape the joints. Untaped joints increase the risk of wind driven rain possibly coming in up the overlaps. Water coming through might not be through the membrane, it might be through the overlaps.

WJ: We’ve certainly seen wind driving rain through overlaps. Taping membrane sections is hard on a roof, especially when it is draped between the rafters.

KP: And what advice would you give to a project where a membrane has been exposed for several months and there’s bad weather forecast?

SM: Best practice is to use temporary protection, like tarpaulin. It’s particularly important in refurbishment or retrofit if people and property are in the building, or if internal linings are in place. It might be less critical for a new-build where some water ingress could be tolerated or the building isn’t weathertight anyway.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check