Why Are There Two Different Methods for Assessing Condensation Risk?

The construction industry uses two different methods of assessing condensation risk in buildings: a single state (i.e., simplified) calculation and a (more complex) full numerical simulation.

The former is known as the Glaser method, and is defined in BS EN ISO 13788:2012 Hygrothermal performance of building components and building elements. Internal surface temperature to avoid critical surface humidity and interstitial condensation. Calculation methods.

The standard recognises the limitations of the method, pointing out that it only assesses condensation risk due to water vapour diffusion (section 1, item (b)), and identifying potential sources of error due to simplifications in the calculation process (section 6.3). We’ll touch on this further shortly.

Numerical simulation is defined in BS EN 15026:2023 Hygrothermal performance of building components and building elements. Assessment of moisture transfer by numerical simulation.

The method analyses heat, vapour and moisture transfer through a building element to give an accurate measure of temperature, relative humidity and water content within the element over a specified time period.

These calculations are often called WUFI® calculations, named for the Wärme Und Feuchte Instationär (translation: heat and moisture transiency) software developed by the Fraunhofer Institute for Building Physics in Germany. The software operates in accordance with BS EN 15026.

How Is Glaser Method Modelling Carried Out?

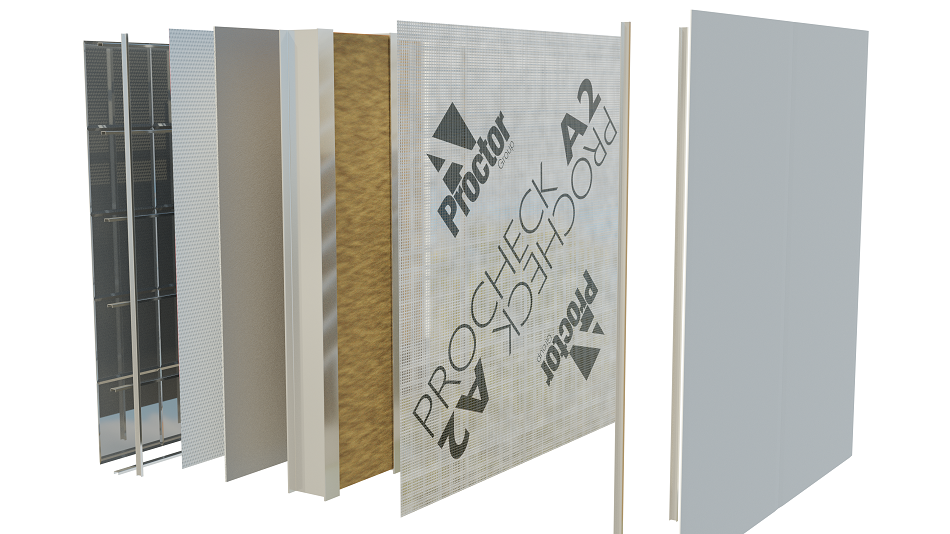

Many of the software packages that offer simplified U-value calculations also offer condensation risk analysis based on the Glaser method. The material layers of an element build-up are entered in the same way, with the addition of vapour resistance/resistivity properties.

For this reason, many construction product manufacturers supplying U-value calculations also include a condensation risk analysis as well.

Vapour diffusion refers to how easily water vapour can pass through construction materials. The simplified calculation uses average monthly temperatures, vapour pressure and steady state conduction of heat to determine if critical condensation points are reached within one year. In some constructions, any condensation at all is considered a failure in the calculation. In most, however, it is generally accepted that all condensation is seasonal, evaporating in warmer months. A worst case ‘Fail’ condition from a Glaser analysis means that there is condensation which does not dry out, and so accumulates year on year.

The calculation is based on the difference between the internal and external temperature and relative humidities. The greater these differences are, the higher the corresponding vapour drive will be, which will equate to a more significant risk of condensation. This means that there is a much higher risk in high humidity areas such as swimming pools.

How Are WUFI® Calculations Carried Out?

Modelling in the WUFI® software starts by taking the inputs as material layers, much like a Glaser calculation. Unlike Glaser, however, most materials are pulled from tested sources, with a library of materials that have undergone real world testing to determine their values. It is possible to create your own, untested materials, though the practice is discouraged.

The layers are automatically ‘sliced’ into a grid, finer towards the interfaces between materials and coarser in the middle of the material. This allows the software to calculate what’s happening through the whole element, while having more precision where needed. The simulation can also support sources of heat or moisture, or use a combination of these to replicate the effects of air exchange, at any depth in any material.

Other inputs include the orientation and inclination of the element, surface coefficients (e.g., darker surfaces absorbing more heat), and climate. More detailed climate data is used than in the Glaser method, and better outputs are achieved when hourly, rather than monthly, climate data is used.

Depending on the complexity of the construction, they can take some time to input the data they require, and longer to run the simulation itself. Where the Glaser method provides a simple pass/fail result, numerical simulation requires the results to be analysed and understood, and this can be considered the really time-consuming part of the process.

How Do I Know Which Is the Correct Method to Use?

Just because a Glaser method condensation risk analysis can be provided for a particular build-up, it doesn’t mean that it is the appropriate method to use. Among the limitations of the simplified method are that it assumes vapour only moves one way (from inside to outside), doesn’t account for driving rain, and doesn’t allow for the absorption or porosity of materials. Other than vapour diffusion, capillary action is one of the main methods of water movement in a construction element, which the Glaser method does not account for.

This latter point is especially important in traditional/historic building fabric, and solid wall constructions in particular. Moisture movement in these situations is particularly sensitive: the ‘breathability’ of materials is critical, and sometimes the building fabric has to dry to the inside.

Other situations where numerical simulation is best used include where hydroscopic materials are in locations where they could absorb a lot of moisture. For example, the A. Proctor Group technical team used WUFI® software to analyse a roof construction where there was a risk of moisture accumulating in an OSB sheathing board during a leak, to assess how it would dry.

To reflect the most up-to-date understanding around moisture movement, BS 5250:2021 Management of moisture in buildings. Code of practice introduced detailed guidance around which assessment method is the most appropriate to use in a wide variety of situations.

If There Are Limitations on The Glaser Method, Can I Trust It?

In the design and construction of most building elements, observing best practice around insulation products, together with airtightness and moisture control membranes, all in the correct respective positions, should avoid condensation risk.

This is reflected in BS 5250’s recommendations. For some floors, walls and roofs shown in the standard, the recommendations are “based on practical experience and are sufficient to provide robust designs” (see 13.2.1.2). For many others, the Glaser method is ‘good enough’, and the use of detailed numerical simulation can be saved for construction types that need it.

What WUFI Calculation Service Does APG Offer?

The A. Proctor Group offers numerical calculations in accordance with BS EN 15026, using WUFI® software, to support customers using products such as Spacetherm® aerogel insulation and Procheck® Adapt VCL.

We aim to help ensure that building envelopes effectively balance heat, air and moisture management to provide healthy and comfortable internal environments.

Find out more here: https://proctorgroup.com/wufi

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check