Membranes installed in the walls and roofs of timber frame kits perform a variety of functions, depending on the specification of, and performance required from, the overall build-ups. In a pitched roof, the underlay provides secondary weather protection below the roof covering. In timber framed walls, membranes might provide air tightness, weathertightness, vapour permeability and/or contribute to thermal performance, depending on their positioning.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check

Product Information

Case study: one-off timber frame kit home in Aberdeenshire

A private client in Aboyne, Aberdeenshire chose a timber frame kit supplied by local manufacturers Brudon Timberframe (part of Brudon Joinery Ltd) for their new-build house. DJW Joinery Ltd was appointed as contractor for the project, and the kit was erected in the spring and summer of 2025.

The challenge

The house is one of the larger projects undertaken by DJW Joinery, with around 500m2 of slate installed on the roof. During construction of the timber kit, the weather was generally favourable and aided smooth progress. However, timber frame kit manufacturers can’t choose when their systems are built on site or the conditions that will be encountered during the build. As such, the components they supply as part of their systems have to contribute to the performance of the finished build, come rain or shine.

The solution

Brudon Timberframe supply two Proctor Group products as standard with their timber frame kits. The walls feature Brudon Timberframe’s own-branded Proctorwrap Reflect®, while the unmistakable purple of Proctor Air® acts as the pitched roof underlay.

“We’ve installed Proctor Air a few times now and it’s very good – it doesn’t behave like other products.” Duncan Wright – owner, DJW Joinery Ltd.

How does an air permeable pitched roof underlay benefit timber frame kits?

As an air permeable pitched roof underlay, Proctor Air simplifies pitched roof constructions. This is a valuable benefit on any product, but especially so for timber frame kits. Customers for manufactured timber frame systems, including the one offered by Brudon Timberframe, include self-builders and so simplicity is of the essence.

The term ‘self-build’ now has a variety of meanings, and can include the ‘self-builder’ engaging the services of a contractor, as was the case in Aboyne.

Duncan Wright, owner of DJW Joinery Ltd, had installed Proctor Air on several projects before working on the Brudon Timberframe kit. While the time of year in this instance was good for roofing work, he has installed it in a variety of conditions before, including wind, rain and during winter. Simplicity therefore benefits everyone, even experienced installers.

Like all modern ‘breathable’ (low resistance, or LR) membranes, Proctor Air allows the passage of moisture vapour. With a vapour resistance of 0.075 MNs/g (or Sd value of 0.015m), it is one of the highest performing vapour permeable membranes on the market.

Proctor Air is not just an LR membrane, however. It is an APLR membrane, meaning it is also air permeable. Its three layers use a combination of technologies that mean condensation risk in the roof space is reduced. Air permeability also provides consistent ventilation and a more uniform flow of air compared to normal vents. Proctor Air also requires no vapour control layer in the ceiling.

“Proctor Air is very good – it doesn’t behave like other products,” said Duncan. “And obviously it’s an advantage not to have to install ventilation products in the roof too.”

This saves self-builders and contractors money, speeds up the roof construction, and means ventilation is assured in even the most complex of roof forms.

What other benefits does Proctor Air offer to self-builders and contractors?

Regardless of the weather that can be experienced in the north-east of Scotland, and the UK more generally, Proctor Air offers water holdout performance and wind uplift resistance that can help roof systems to cope with more frequent extreme weather driven by climate change.

Pitched roof underlays provide secondary weather protection, so they are water resistant – not waterproof (the roof covering is always the primary protection). This needs to be considered during the construction phase, especially if timescales become extended or where roof coverings may be on long lead times. While Proctor Air has a W1 resistance to water penetration classification, when tested to EN 13859-1, it should be temporarily covered if adverse weather is anticipated.

In addition, a hydrophobic additive in all three of its layers helps it to achieve a minimum of 1m hydrostatic head. This level of water resistance meets the guidance of NFRC’s Technical Bulletin 6.

Other features of Proctor Air were designed to make life as simple for the installer as possible and give confidence both during, and long after, installation:

- It is one of very few membranes which can be used in wind zones 1-4 without additional measures such as taping joints or additional battens:

- It achieves an excellent Mullen burst strength result (an assessment of the fabric’s strength), which helps it to resist normal roof installation loads.

- Its slip resistance has been assessed and it has a high coefficient of friction, for increased safety during the installation of the covering as part of normal safe working practices.

How does a reflective breather membrane perform in a timber frame kit?

A vapour permeable membrane in the external walls of a timber frame building allows the passage of moisture vapour, reducing condensation risk. Like a pitched roof underlay, it can also provide secondary weather protection behind the primary covering.

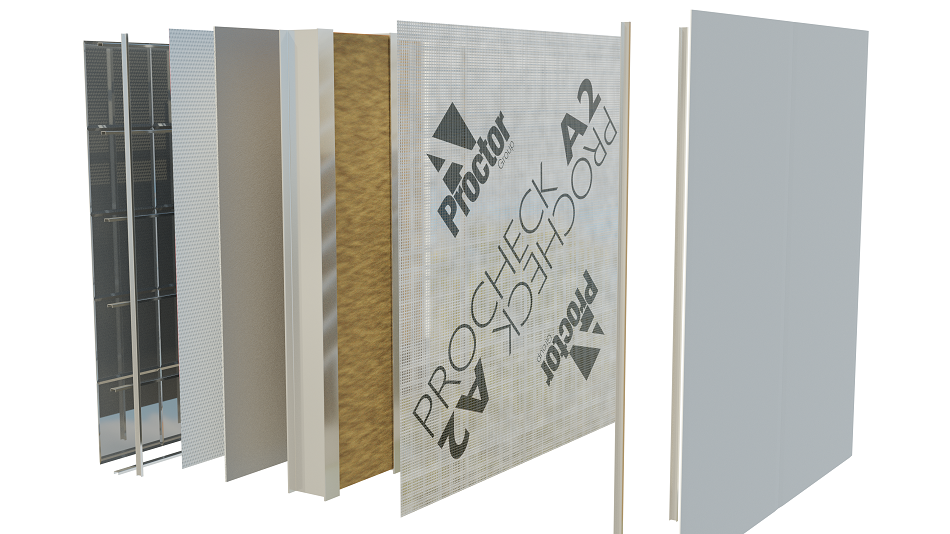

As part of Brudon Timberframe’s manufactured timber frame kits, Proctorwrap Reflect’s low emissivity foil also contributes to the overall thermal performance of the wall build-up.

The membrane changes the way heat transfer takes place across an adjacent air cavity, allowing a higher thermal resistance to be claimed for the air space in U-value calculations. This plays a crucial role in helping to lower U-values without having to rely solely on increasing insulation thicknesses.

Proctorwrap Reflect, which is Q-Mark certified by BM TRADA, has a W2 resistance to water penetration classification, meeting the standard required for external walls. While it should be covered as soon as practically possible after installation, it is possible for the primary wall covering to be installed up to three months later – giving self-builders and their contractors peace of mind on projects where the pace of work is not necessarily the same as on volume housebuilding sites.