Keira Proctor (KP): How does technology impact interpretations of building regulations?

Adam Salt (AS): Technology should be used to improve communication about updates. You can have changes to building regulations and sometimes people won’t know about it for months.

KP: How are changes announced?

Will Jones (WJ): Public announcements outline changes or amendments in the documents. Then the onus is on the user of the regulations to go and read the document and understand the changes and the potential impact on their work.

AS: We deliver CPDs all the time where we explain about a change and the audience say, “Oh, I didn’t know that.” Everyone’s busy with their day jobs and don’t necessarily know when change is coming or what it requires.

WJ: As a manufacturer, we stay on top of regulations that impact us and our products. But architects have to understand ALL of it, and that’s not as simple.

AS: Regulations also refer to other standards that get updated, so there is a lot to keep on top of.

KP: From contributing to the development of standards, we know the process can take months, if not years. There is an opportunity to make things simpler.

WJ: We understand there’ll be a massive overhaul of regulations in the coming years. What form will that take? How will people adapt to so much fundamental change? The right kind of portal to provide access will be important.

KP: Are building regulations overly complex?

AS: They’re daunting and hard to interpret. We’ve seen many projects where different interpretations of the same regulation causes issues.

KP: Local authorities struggle to apply the guidance uniformly. Developers go to local authorities and get different answers, which is a barrier.

WJ: They’re not very black and white. You speak to one person and get advice; speak to another, equally qualified person and get a different perspective. It leaves you wondering, “How can there be this ambiguity?”

AS: Makes it challenging for manufacturers too, delivering products into the market.

KP: Can regulations keep pace with innovation?

WJ: Innovation should always be ahead. We see that in all walks of life – motor sport is a good one, where teams push to go faster and regulations then curb developments to ensure everything is properly governed. Building regulations need to be closer to things like MMC and modular offsite, which would then support greater adoption of them.

AS: It’s not just regulations. Accreditations and certifications are good things but they also make it expensive and time consuming to introduce new ideas to the market.

KP: For a new product, it can be a year for certification, plus the costs that come with that.

AS: We’ve spoken to people with some great solutions for the construction industry, but they haven’t brought them to market because they wouldn’t see a return. That’s a real shame.

KP: Requirements shouldn’t be a barrier, but there’s a balance to be struck because you don’t want poor quality/poorly performing products coming in.

AS: There’s a lot of focus on manufacturing at the moment. But you don’t start making a product until you’ve designed a solution, and until you’ve looked at the regulations and said, “What do I want to achieve? Where does my solution fit within the regulations?” It starts with regulations, and a clearer route would help innovation.

WJ: Agreed. You start with an existing problem and design a solution to address it.

KP: We see it in the wording, “or similar approved” in specifications. Interpretations of that phrase can vary significantly, there’s huge ambiguity.

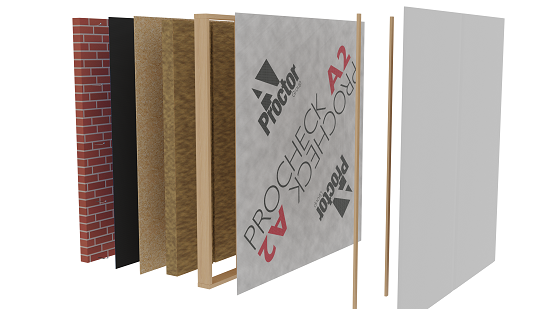

AS: It’s a problem in our industry, where membranes can appear very similar but there are big differences in product specifications. Some variations in performance are small, some are massive, but if you’re not aware of them then products can appear the same at face value.

WJ: “We need a breathable membrane, so any will do,” right?

AS: But you have airtightness, vapour permeability, self-adhesive/non-self-adhesive, different fire performance, low emissivity facers. The list goes on.

KP: It’s misleading and confusing, which is worrying. But you can’t expect a specifier or installer to know everything about everything, so that’s where it falls on manufacturers to be responsible and transparent about correct applications and clear/correct information about their products.

Watch the full conversation on the A.Proctor Group YouTube channel, or listen wherever you get your podcasts.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check