What is changing – and what does that mean for the roof?

Critical to understanding the most appropriate product choices for a project – including pitched roof underlays – is appreciating the overall scope of the work being done.

Is it ‘just’ the recovering of the pitched roof? Or is the thermal performance of the roof being upgraded at the same time? If so, what does that mean for how the roof is ventilated?

Among the heritage buildings our products are used on, a common example is that of a church undergoing a wider renovation. Often, the aim is to bring the building back into regular occupation by incorporating new or reconfigured spaces designed for a mix of uses.

When that is the case, what are the potential impacts of new/increased use on the traditional building fabric? More people means a likelihood of more moisture being generated within the building. Depending on the building’s overall ventilation measures, a lot of that moisture could find its way into the roof space – especially as the ceiling is unlikely to have a modern air and vapour control layer.

Is a product certified for the intended application?

There’s a reason that Proctor Group has adopted the mantra: “not all membranes are the same.” Unfortunately, we still see many examples where an underlay has been used in the wrong situation.

For example, perhaps not every membrane is certified for use with sarking boards, as is traditional practice in Scotland.

If a heritage roof has a specific design feature or traditional construction method, then the underlay should be chosen with that in mind. If product accreditation, like a BBA certificate, doesn’t address a specific scenario, then contact the membrane manufacturer for technical support.

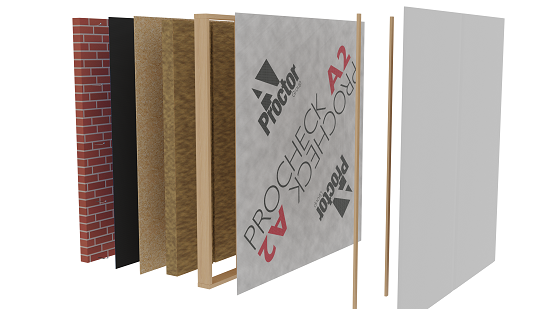

Air permeable membranes balance performance and tradition

Using an air permeable LR pitched roof underlay, allows complex roof designs to be managed without additional ventilation, that may be required with airtight membranes.

Modern ventilation products and accessories have a notable impact on the aesthetics of a traditional roof. That’s why many roofing contractors are turning to air permeable low resistance (APLR) membranes, like Proctor Air® for heritage projects.

Proctor Air is one of the highest performing vapour permeable membranes available, with a vapour resistance of 0.075 MNs/g (Sd value of 0.015m). As well as allowing the passage of moisture vapour from the roof space, its air permeability provides consistent ventilation and a more uniform flow of air from a cold roof space compared to normal vents.

No vapour control layer is required in the ceiling, which is beneficial where an existing ceiling is being retained and cannot be altered. Overall, the combination of features reduces condensation risk in the roof space, even when the use patterns of the building change as well – and all while avoiding the need to install vents in the roof.

One roofing contractor told us about a church project they worked on, and said: “The air permeability of Proctor Air makes it very versatile for us. The building featured a traditional pantile on a mortar-bedded creasing tile eave. Proctor Air gave us a breathable roof without sacrificing the traditional elements, and while maintaining the original appearance of the building.”

User-friendliness matters as much as performance

Another common aspect of feedback on Proctor Air is its user-friendliness. Practical questions about a pitched roof underlay that matter to installers include: does it tear easily? Will it cut well, or do the edges fray when you run a knife through it?

For example, in an assessment of the fabric’s strength, Proctor Air achieves an excellent Mullen burst strength result. This helps it to resist normal roof installation loads. In addition, an assessment of its slip resistance shows it has a high coefficient of friction, which increases safety during the installation of the covering as part of normal safe working practices.

When you’re installing an underlay and working with traditional or unfamiliar details, it helps to have a membrane that you don’t have to think twice about while using.

For more information, visit https://proctorgroup.com/products/proctor-air

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check