There are a host of factors to take into consideration when comparing: third-party certification; accessories and extra processes; the testing behind the declared performance data.

And then there’s something that is arguably thought about much less, if at all. What is a product like to install? To understand that means listening to the installers, which is what happened at Great Charles Street in Birmingham.

Changing AVCL Specification to Get a Better Result

Moda Living’s 722-home build-to-rent scheme comprises a mix of one-, two- and three-bedroom apartments, including some penthouses.

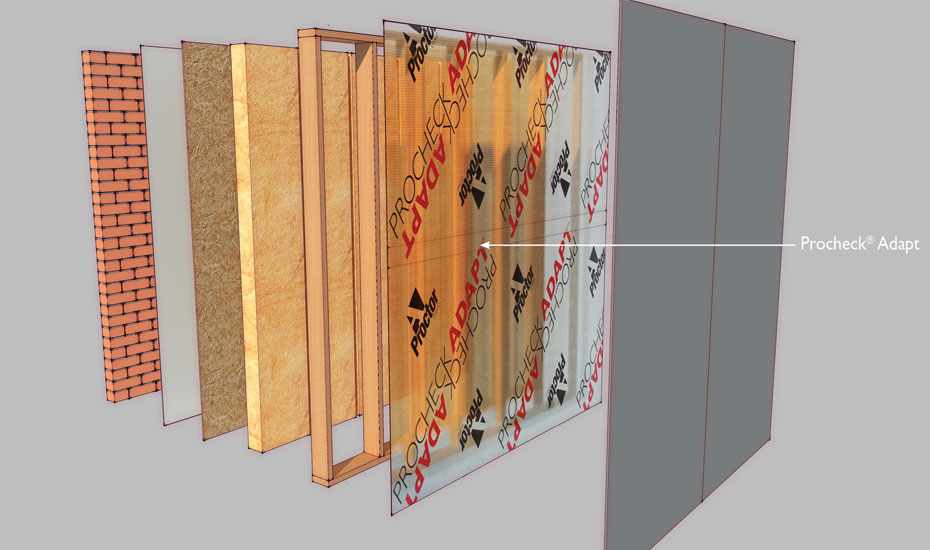

The 16-storey block B and the 5/6-storey block C of Great Charles Street both feature a concrete frame with brickwork finish. The choice of external wall build-up meant the airtightness line was specified internally.

The specialist contractors delivering the internal fit out package therefore began installing the chosen air and vapour control layer (AVCL) membrane to the internal face of the walls.

However, it quickly became clear that a change needed to be requested. The Project Manager started receiving feedback from the team on site that the membrane wasn’t the easiest to cut or handle. A decision was therefore made to change to Proctor Group’s Procheck® A2 membrane.

The reviews improved immediately. The installers found it better to use and easier to install, saving time. From that point, the team continued to use the new product.

Procheck A2 is a vapour and airtight membrane. Its composition gives the membrane a high degree of vapour controlling properties, as well as being airtight. That allows it to be used as an AVCL and helps contribute to the thermal efficiency of the building due to its’ reflective surface.

It is also rated A2-s1,d0 when classified to BS EN 13501-1, meaning it is considered non-combustible with limited contribution to fire and can be used in relevant buildings and those over 11m/18m.

Better handling and faster installation make a big difference on any project, but especially on sites like Great Charles Street. With an internal airtightness line, installers have to work around a lot of penetrations, including ducts, pipes and brackets.

When any single penetration could be a source of failure when it comes to airtightness testing, a product that cuts and handles well reduces the potential risks of failure.

Combining Product Performance with Quality Control

Even when installers find a product is easier to handle and use, long-term building performance still depends on a high standard of quality control.

Thorough checking of the on-site team’s work also played a significant role at Great Charles Street. That meant encouraging as many people as possible to view the installation and provide feedback before it was covered up.

Block managers from the main contractor checked all the work. The specialist contractor also requested a site visit from Proctor Group’s technical team, who produced a report on the quality of the installation.

The change in product and the approach to quality control has paid dividends. Finished apartments that have been airtightness tested have averaged results below 2.0 air changes per hour (ACH) at 50 Pascals pressure.

Compare that to the minimum standard of 5.0 ACH required by the Building Regulations, and it gives an indication of the performance and thermal comfort that eventual occupants can expect to enjoy at Great Charles Street – thanks in part to a well-made product substitution.

Find out more about Procheck A2: https://proctorgroup.com/products/procheck-a2

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check