What does NFRC Technical Bulletin (TB06) say about water resistance of pitched roof underlays?

Referenced in BS 5534, the code of practice for slating and tiling pitched roofs, NFRC TB06 describes fitness for purpose of pitched roof underlays.

Among the performance characteristics it details, the bulletin says, “a water hold out over 1m when tested to BS EN 20811 will be adequate. Class W1 membranes are to be preferred as defined in BS EN 13589-1.”

Why is the water resistance of membranes critical in the short term?

When a roofing system is installed, there is an inevitable period of time where the underlay will be in place without a roof covering to protect it. The underlay might therefore have to bear the brunt of any inclement weather. This is particularly critical in retrofit or refurbishment projects, where occupants are might still be in the building during construction work.

It is good practice not to leave underlays exposed longer than necessary, but it can be possible for them to provide temporary weather protection. Proctor Air®, for example, can be left exposed for up to three months, although should not be relied upon as being waterproof.

And what about in the long term?

As the frequency and intensity of extreme weather increases as a result of the changing climate, roof systems generally – and membranes as a specific part of those systems – need to be capable of withstanding more severe levels of rainfall. An underlay’s ability to perform with a 1m head of water is a minimum level of performance that specifiers should look for during product selection.

How does Proctor Air perform in terms of water resistance?

Launched this year, Proctor Air is the A. Proctor Group’s pitched roof underlay for the future. It is an air permeable, low resistance (APLR) membrane designed to simplify pitched roof construction. The performance offered by Proctor Air can help to ensure that roofs are capable of performing even in the face of extreme weather and climate change.

In terms of water resistance, each of the three layers that make up the total underlay thickness has a hydrophobic additive. This gives Proctor Air a hydrostatic head of water over 1m, which is confirmed in the product’s BBA certificate 24/7147.

Tested in accordance with BS EN 13859-1:2014 Flexible sheets for waterproofing. Definitions and characteristics of underlays – Underlays for discontinuous roofing, Proctor Air achieves a water resistance classification of W1.

What is the BS EN 13859 water resistance test?

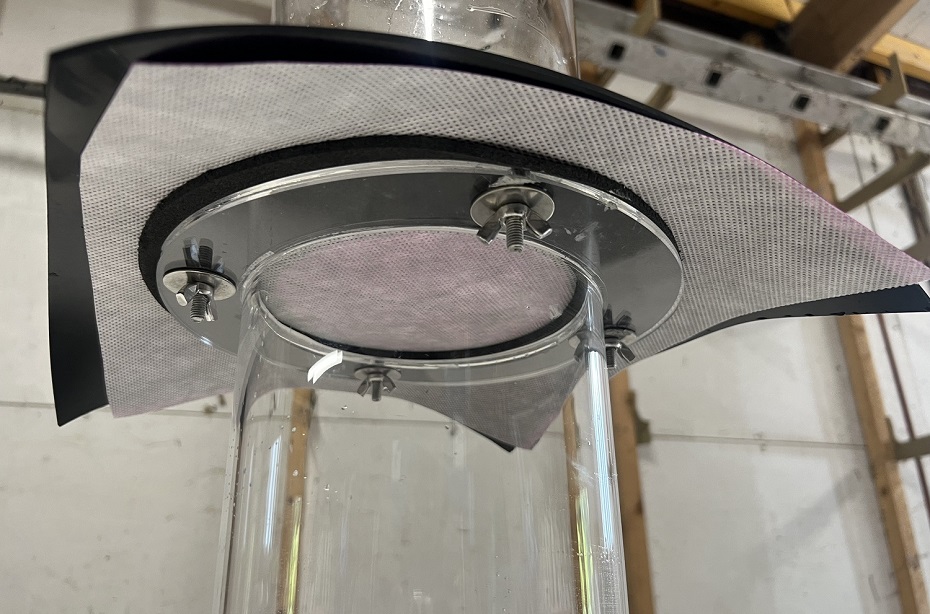

To achieve a W1 classification, an underlay essentially is subjected to the equivalent of driving rain for two hours.

A sample of the underlay is placed in the test apparatus for two hours with a 200mm head of water on top of it. If any water droplets are found in the bottom section at the end of the test, then the membrane cannot be classified W1. For the purposes of our own internal testing, we consider any water penetration through the membrane sample to be a failure.

What effect does water have on tile batten timber treatments?

The timber used to make tile battens is treated to help ensure its performance and longevity. When water comes into contact with battens, the treatment can be released from the timber. There is concern that, when released, these timber treatments could compromise the integrity of pitched roof underlays.

Do timber treatments affect the water resistance of pitched roof underlays in terms of water hold out?

- Proctor Group has been carrying out additional testing to check whether Proctor Air still achieves a W1 classification if tile battens release their timber treatment.

We submerged different types of battens, featuring a range of timber treatments, in water for a minimum of 72 hours. We then carried out the BS EN 13859 water resistance test. The batten types tested were Donaldson Timber BS5534 Graded Blue Battens, Marley JB Red Battens, and Green Treated Battens.

The whole process was repeated, testing Proctor Air twice to ensure consistency of results. In all three cases, and across both sets of tests, Proctor Air continued to pass the test and achieve a W1 classification. These results show it to be unaffected by tile batten timber treatments. Tests done on other underlays, meanwhile, did show that the W1 classification could be compromised by the treatment in the water residue.

What can roofing contractors and clients do if they are concerned about tile batten treatments and underlay performance?

Many different timber treatments are used with tile battens. For the purposes of internal testing, the A. Proctor Group selected commonly-used timber battens. Clients should check with their underlay manufacturer if their membranes still achieve a W1 classification if timber treatment is potentially released from tile battens.

To conclude, the tests have shown that the water hold out properties of Proctor Air were not negatively affected after being subjected to various types of reputable timber treatments. For further advice, please contact the technical team at the A. Proctor Group.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check