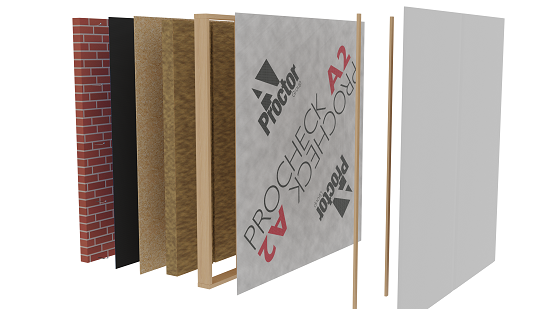

The right membrane products contribute to making structural insulated panel (SIP) systems simpler and faster to install. By realising these benefits in offsite manufactured SIP systems through membrane specification, and then applying modern methods of construction to maximum effect, the construction of new homes can become more efficient. Not only are the UK’s ambitious housing targets then more viable, the severe lack of affordable housing could also be addressed.

Case study: Next generation SIP technology and the Ultrapanel demonstration house

Ultrapanel Building Technologies showcased their next generation SIP system technology by constructing the Ultrapanel demo house – a template for what volume housebuilding delivery and affordable housing could look like in the next few years.