Completely remodelling the bathroom offered the opportunity to also make improvements to its thermal performance – as long as the chosen solution didn’t encroach on the available floor space too much.

“The bathroom was a very cold part of the home,” said Ian. “We knew we wanted to include insulation, but we also didn’t want to compromise on losing too much floorspace which would impact on our choice of bathroom furniture.”

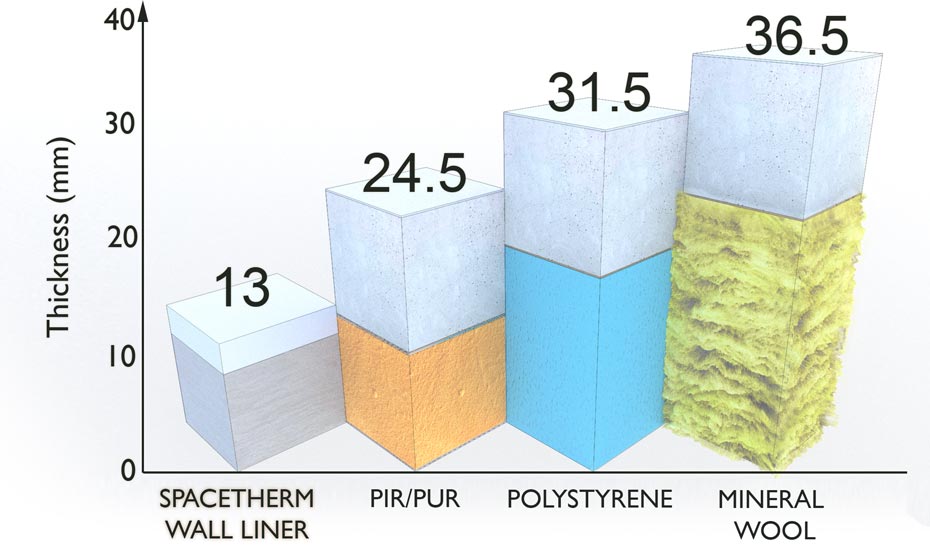

In other areas of the house, Ian has gone down the route of using wood fibre insulation boards to deliver improved thermal efficiency from the external walls. The bathroom’s tight space meant he needed a solution that could deliver a meaningful improvement in thermal efficiency while limiting the loss of internal floor space.

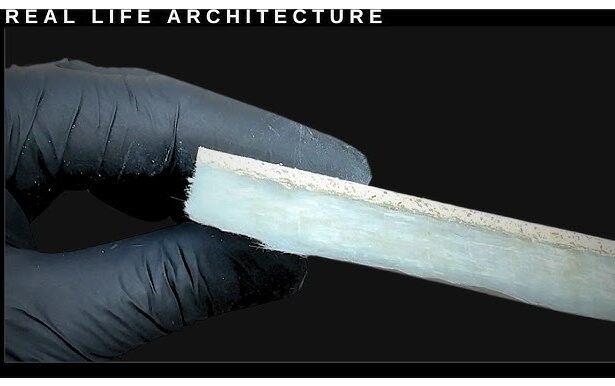

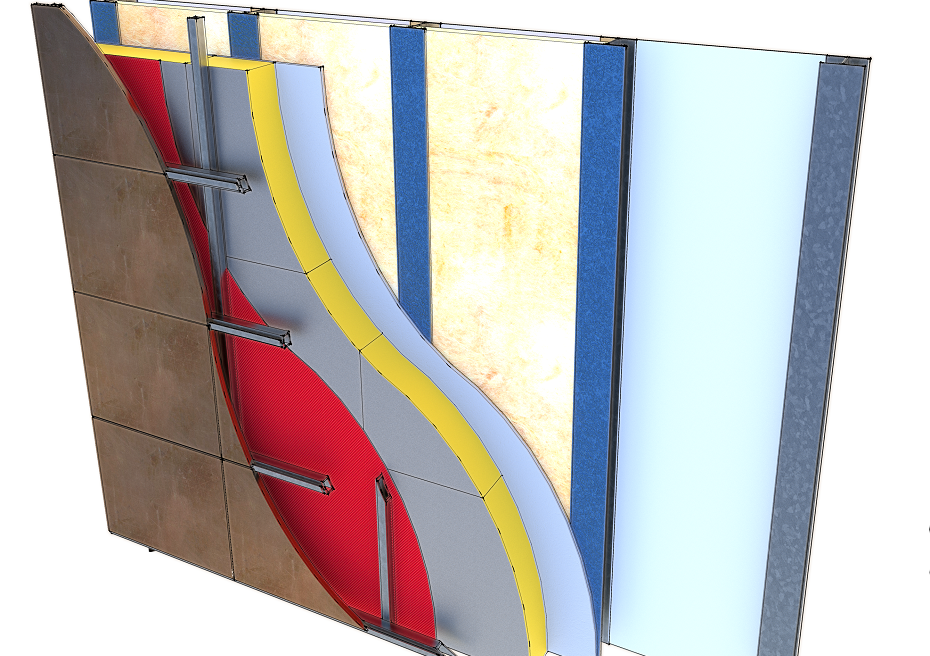

That is where aerogel insulation, and Spacetherm® Multi in particular, came in. Comprising aerogel insulation blanket – a material derived from silica gel and originally developed by NASA – bonded to 6mm magnesium board (MgO), the Spacetherm Multi could be installed directly to the bathroom’s single external wall and window reveals with stainless steel fixings.

“When I deliver retrofit projects for my clients, simplicity is key,” said Ian. “This is why I opted to aerogel insulation, because as long as the wall was reasonably level then there was no need to use timber battens, which would have negated the space-saving benefits of the aerogel’s thermal performance.”