Key takeaways

- Removing existing windows from solid-walled buildings can uncover a host of potential issues, including significant gaps within the reveals.

- Trying to remedy such issues while leaving the current finished reveal in place risks compromising the intended benefits of the new window installation.

- A poorly finished and poorly performing reveal could lead customers to believe their new windows are faulty, and reflects poorly on what might otherwise be a quality installation.

- Aerogel insulation is the ideal solution for maximising window size within the existing opening, while improving the thermal performance of the window reveals.

Why does heat loss at window reveals matter so much?

In traditional buildings featuring solid wall construction, window reveals are a significant cold bridging risk. First of all, if the building has moved or an old window has warped, or was poorly fitted originally, there can be large air gaps which mean heated warm air is passing directly to the outside.

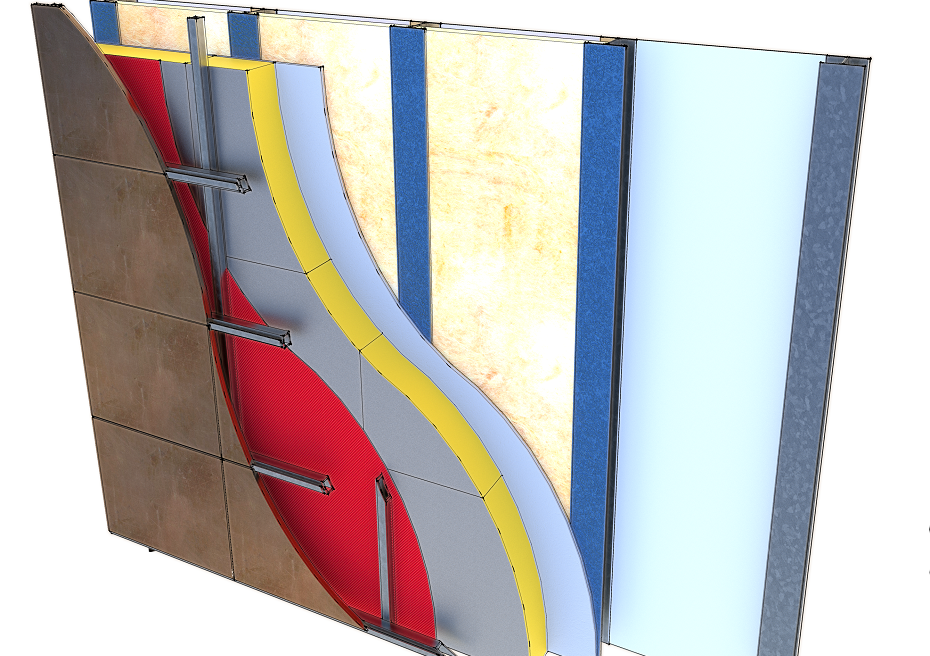

Even with a well-fitted and well-sealed window, solid masonry allows heat energy to bypass the window through the edge of the masonry wall. Compare it to modern cavity wall constructions, which feature insulated cavity closers around the edge of window and door openings to combat this issue.

Fitting replacement windows offers an obvious opportunity to address air gaps. Depending on the shape of the opening, it may be necessary to address larger gaps with sealant or foam that makes a minimal contribution to the overall thermal performance of the installation.

Even where the new windows fit their openings with acceptable tolerances, the potential improvement that the new window offers compared to the old one could drive a higher rate of heat loss through the window reveal, leading it to become relatively colder.

Should window reveals only be insulated as part of internal wall insulation?

There are plenty of potential benefits to insulating window reveals, regardless of whether internal wall insulation is being installed or not. Addressing the thermal performance of window reveals should therefore be considered even if a wider retrofit project is not being undertaken.

Internal wall insulation is a common retrofit measure for existing buildings looking to achieve better energy efficiency without changing the outward appearance of the building. As windows form part of a building’s thermal envelope, addressing how they link to any new insulation strategy is a vital part of reducing risk in retrofit – even if the windows aren’t being replaced at the same time.

Where window replacement is taking place in isolation, taking the opportunity to insulate the window reveals at the same time could be highly beneficial in future, should the homeowner decide to install internal wall insulation as part of a separate project.

If they never choose to go down the route of internal insulation, they will still get the benefit of well-finished and well-insulated reveals for the service life of the windows.

What benefits does a window reveal insulation board offer to installers?

Working on traditional building fabric can uncover all sorts of issues that are not apparent at first glance. The more a building has been altered over the years, the more likely it is that someone chose to cut corners and do the bare minimum.

As such, it’s not uncommon to find that window reveals are a real weak area. Not only are they uninsulated, but they may have significant air gaps behind the existing finish. While it might be tempting to simply fill such gaps with an expanding foam, this risks damaging the existing finish (especially if the foam expands too much) and leaving the customer with an extra problem to resolve after the window replacement is complete.

In addition, expanding foam offers little to no thermal benefit, and therefore does nothing to address the window reveal’s contribution to energy efficiency and occupant comfort.

By being proactive and offering a proven insulation solution for reveals alongside the replacement windows, installers can demonstrate their commitment to a high-quality end result that minimises the risk of a poor finish and delivers more than the homeowner might have originally expected.

What is aerogel insulation and Spacetherm WRB?

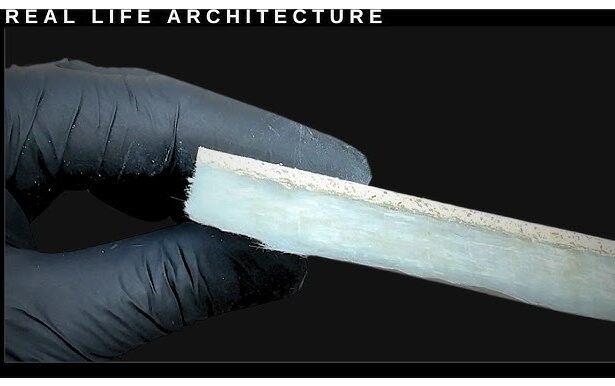

Aerogel is made through a process where silica gel is freeze dried until the liquid component has dried out and been replaced with gas. The result is a lightweight material that is ideal for insulation in space-critical applications, thanks to it having a low thermal conductivity, as well as being hydrophobic and vapour open.

At Proctor Group, we use aerogel insulation to produce our Spacetherm range, which includes WRB specifically for window reveal applications.

WRB consists of Spacetherm aerogel insulation blanket bonded to plasterboard or magnesium board, with or without plywood reinforcement, depending on fixings. We offer WRB cut to size, to avoid waste and reduce cost to the installer.

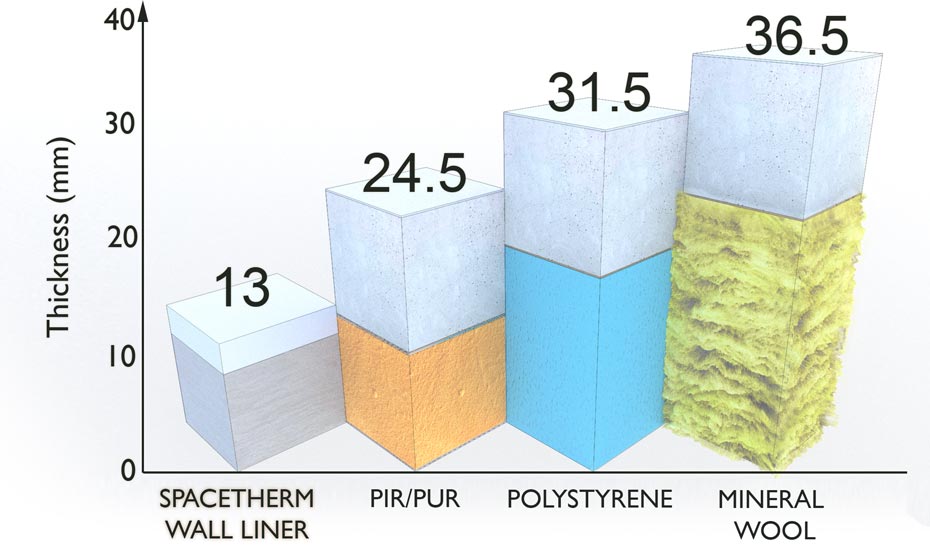

The thermal performance of aerogel insulation is slightly better than that of a rigid PIR insulation board. Crucially, where most PIR boards are only offered at 20mm or 25mm thickness, the aerogel component of WRB is just 10mm.

As a result, replacement windows can be sized to accommodate the reduced thickness of window reveal insulation, allowing installers to offer the largest windows possible for the opening.

What to do next

Find out more about the Spacetherm range or, to discuss how Spacetherm WRB could be part of your window replacement service, contact us.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check