Collaboration key to creating new living units

Social Bite opened the Social Bite Village in Edinburgh in 2018. The site is a highly supported community for 20 people and, in that time, it has served as a transformative, transitory space for 100 people experiencing homelessness.

With the lease on the current site coming to an end, Social Bite has worked with the local council to find a new site in the city. This will involve the relocation of the eleven current two-bedroom living units, plus the addition of five new one-bedroom Nest homes and a community building (comprised of six modules).

Two further brand-new sites, in South Lanarkshire and Dundee, are also in development.

“Creating the new one-bedroom unit was a very collaborative process,” said Richard Miller, Project Manager at Social Bite. “Ecosystems Technologies put forward concepts for the buildings. We received their technical steer and used our own architects and engineers to make sure that relevant regulations were met.”

“We produced a prototype Nest house in 2023,” said Owen Young, Production Director at Ecosystems Technologies. “That really helped people to see what was involved and the quality of the units, and helped to secure additional charitable backing.”

Creating a quality product using offsite modular construction

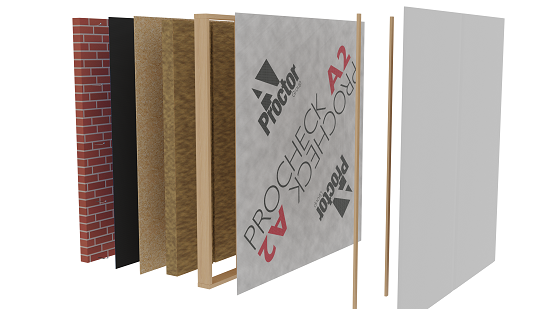

The housing units that Ecosystems Technologies have created for Social Bite exemplify a pioneering approach to modular construction, not just in Scotland but the whole of the UK. Working with their partners, the company uses a vacuum press to form cross laminated timber (CLT) panels for all its modular products.

The modules therefore offer all the typical benefits of offsite manufacture: consistent quality, protection from the weather, minimal finishing, faster project timescales on site, and a high standard of building fabric performance.

“The energy performance of our buildings is unmatched,” said Owen Young.

“We work well with Ecosystems Technologies because of a shared ethos and the aspiration to create quality solutions,” said Richard Miller. “Their modular products are sited across Europe, from the north of Scotland to the south of France. It was important that we offered that same quality in the Social Bite Village, so that people could be proud of where they live.”

The importance of local supply chains

While offsite construction is relatively well established, CLT manufacturing is a relatively immature market in the UK. Yet Ecosystems Technologies is not only leading on it, but doing so using only Scottish homegrown timber. This ensures it is fully traceable and keeps transport to a minimum.

Such a commitment to sustainable materials and local supply chains is reflected in all of the company’s material specifications, and is how they came to recommend the Proctor Group’s membranes to Social Bite.

“We use the Proctor Group’s membranes pretty much as standard,” noted Owen Young.

Proctor Group has supplied three different membranes to the project:

-

Wraptite® UV, which combines properties of vapour permeability and airtightness in one self-adhering product, and is specifically designed for use behind open-jointed cladding. Applied externally, Wraptite UV acts as the main airtightness layer for the units.

-

Procheck® Adapt is a variable-permeability vapour control layer which is capable of adapting to changes in humidity levels, becoming more resistant in winter and more permeable in summer. Applied to the units internally, it protects the fabric from potential condensation risks and is also an airtight barrier.

-

Proctor Air® is an air and vapour permeable, highly water-resistant roofing underlay. Normally used on pitched roofs, in this case it was installed on the flat roofs to provide temporary protection and help to retain the wood fibre insulation.

Speaking about the decision to supply the membrane products and associated tapes, Proctor Group’s Managing Director, Keira Proctor, said:

“Being involved in the Social Bite Villages project has been an incredibly rewarding experience for all involved at the Proctor Group. Supporting such a transformative initiative with our membrane solutions aligns with our values of community and sustainability. It has been a privilege to contribute to spaces that are not only built to last but also meaningful in the lives of those they support.”

More than 17,000 people live in temporary accommodation in Scotland, often spending long periods in sub-standard conditions – isolated, under curfews, and without access to proper cooking facilities.

In contrast, Social Bite villages offer high-quality homes where people can build skills and confidence through support and wellbeing activities, as part of a community, while they wait for permanent housing.

“We spoke to Ecosystems Technologies’ preferred suppliers to try and work with a familiar supply chain as much as possible,” said Richard Miller. “So many of those companies have been really supportive, to a level I haven’t experienced before. Social Bite is very grateful to the Proctor Group for the products supplied and the very helpful technical advice and support.”

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check