Be aware of the frequency of extreme weather

Climate change is causing more extreme weather, more often. Rainfall intensity has increased and will continue to do so. The 1-in-100-year storms we might have previously designed for are now happening every four to five years.

Unfortunately, people are not adjusting their behaviour and their practices to account for this kind of unprecedented weather. They adopt what you might call the ‘typical’ construction industry mentality: we’ve done our work this way for years, and it’s been fine.

In fact, extreme weather is pushing all products used in pitched roofing to their limit.

Underlays are not the primary waterproofing layer

In any pitched roof, the outer covering is always the primary waterproofing layer. What’s particularly concerning is that in some of the storms we’re witnessing, even covering materials like slates and tiles are struggling to cope with the conditions.

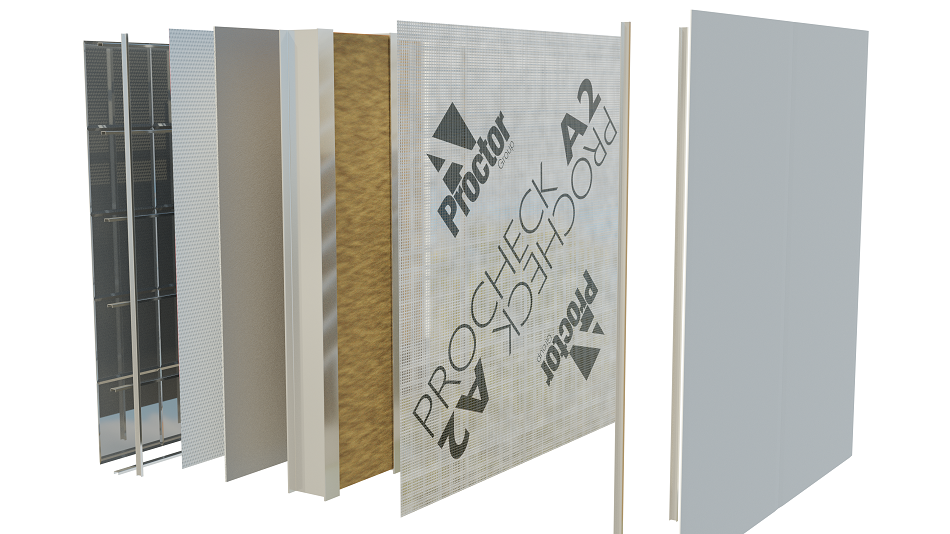

An air permeable membrane, like any underlay, is only a secondary water-resisting layer. If it is to be left exposed for any length of time prior to installing the roof covering, it should not be relied upon to be the primary water hold out.

Membranes are somewhat a victim of their own success. Because they have often provided better protection than they are designed for, people have come to assume the underlay can be left exposed, regardless of the weather. It’s that same mindset in action: we’ve used them like this for years, so the product will be fine.

The question is: do you really want to take that chance?

Make sure to read the installation guidance

The development of these unrealistic expectations means that people often stop reading documents like installation instructions and BBA certificates. This guidance is critical for understanding the nuances of a product and how it should be used, and yet membranes like Proctor Air are installed on a roof even when a storm is coming.

When a document states that a membrane can be left exposed for up to three months, people seem to assume that means water hold out. In fact, the guideline of three months is in respect of UV exposure and potential degradation of membrane performance.

Most certificates actually say that a membrane should be covered as soon as possible, and temporary protection should be used in periods of inclement weather. Don’t rely on the membrane to be primary waterproofing in a storm.

Temperature fluctuations add an extra variable

The composition of a membrane has a big say in how the underlay performs during and after challenging weather conditions. In particular, we’re talking about times when there is wet weather, a sudden freeze, and then a thaw followed by more rain.

A membrane like Proctor Air features a spunbond top layer. Water can get into the pores of the top layer, but the water doesn’t track through. If that water, sitting in the top surface, freezes then it expands – pushing the pores apart.

In the event of a sudden thaw, the top layer of mechanical hold out is compromised and water can get towards the finer internal components – although the hydrophobic additive does help to resist it.

If water tracks through like this, then the underlay requires time to dry. If more rain is forecast, get the underlay covered. Even better, make sure it is covered before the bad weather starts.

Crucially, Proctor Air will return to its previous levels of performance and maintain its W1 classification. And if water does track through, it will never lose its air permeability.

A film laminate membrane, by contrast, will never regain performance if it is breached. The physical damage to the film is permanent, and water hold out performance cannot be regained.

How do we design roofs for the future?

As a membrane manufacturer, we can make the best-performing products possible but there will always be other considerations. Roof pitch affects how quickly water runs off the roof, and orientation affects how much a roof is subjected to wind-driven rain. If membrane laps are particularly loose, will rain get blown underneath the laps?

Have you used staples or nails? Nails push through and seal over the hole, whereas staples can move. There are so many ways in which water could potentially enter a roof construction, especially in periods of extreme weather.

The message we want you to take away from this is: a pitched roof underlay is only one component to consider as part of a holistic roof design. Be aware of the product you’re installing, and remember that acceptable exposure for UV resistance is not the same as weather resistance.

For more information, visit: https://proctorgroup.com/products/proctor-air

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check