Membranes Are Designed for Different Purposes

A membrane may not be certified for the application you want to use it in. A membrane may not even have third-party certification at all. Understanding the nuances of a specific product and how it can be used, and then getting project-specific advice, is essential.

One of our technical team once saw a site where sections of six different membranes had been patched together on a single roof. Such a situation may be extreme, but it perfectly illustrates the point that different products do not behave identically – much as somebody might wish they did.

The first thing to ask about an installation like that is: what is the worst performing product on the roof? The worst performing product is the lowest common denominator, and defines the performance of the whole roof. This particular project featured traditional Scottish sarking, and not every underlay is certified for use in that application.

The next thing to ask is: who allowed that situation to occur? Nobody would specify a roof like that, but the installation has been allowed, inviting the potential problems that come with it.

Fire Performance Characteristics Vary with Substrate

One area in which we have seen the issue of project-specific circumstances come to the fore is, unsurprisingly, fire performance. Assuming one single membrane product can provide, say, a desired Euroclass B classification in every situation is incorrect.

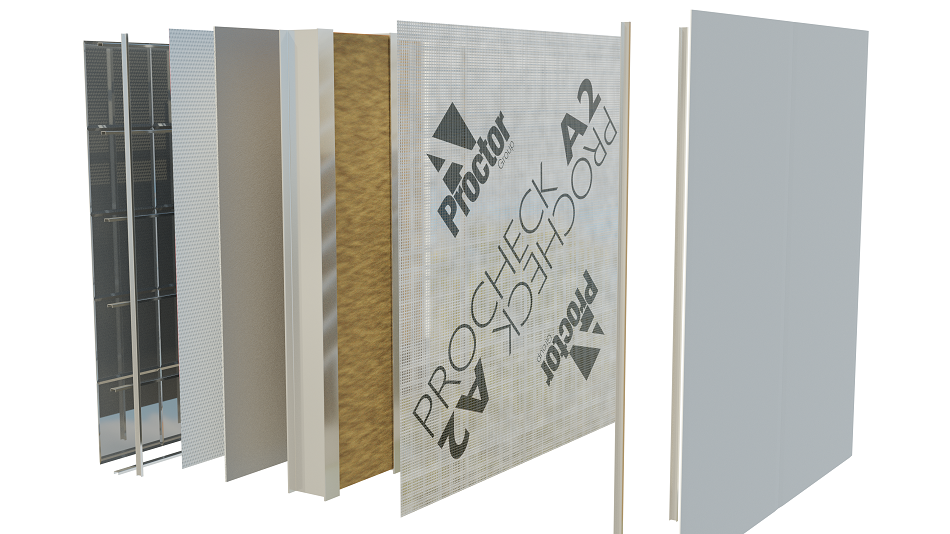

Membranes are thin products and have inherently little calorific value. Their role in a fire depends on what substrate they are installed over and how they are fixed. This can only be established through system testing to measure the fire resistance of a complete wall build-up.

In that context, does the membrane play its part – however limited – in the full system performing as it needs to? Does it help the wall build-up to achieve the R, E and/or I classification required?

A Membrane’s Layers Dictate Its Performance

Manufacturers combine the properties of different manufacturing processes to build up a complete membrane product in layers. They also mix in colours, additives, fire retardants, and so on, to each layer, performing a delicate balancing act of adding performance to a product without having one thing working against one another.

Any reputable manufacturer will be transparent about the fundamental make-up of a product’s layers. It’s worth giving an overview of the different manufacturing techniques to aid in understanding more about the potential differences between products.

Spunbond polypropylene

Polypropylene fibres are put into a hopper and heated up. They come out as very long, thin filaments, which are dropped onto a belt – not unlike spaghetti going onto a plate. A calender then compresses the fibres together, creating a textured finish.

Meltblown polypropylene

The fibres are again melted, but this time blown against a drum to create the filaments. Compared to the spunbond process, the meltblown filaments have a tiny diameter which means they are also much shorter. The spaghetti analogy still applies, but the ‘pattern’ of the filaments is on a much closer and smaller scale. The resulting layer is too fragile to use by itself, but is air and vapour permeable.

Films

Film membranes are extruded. The extrusion process pushes the membrane out under pressure, so there is vapour diffusion but no air permeability. Like a melt blown layer, a film is also fragile.

Layers of different membranes can be combined using offline lamination, where spots of adhesive or heat are used to seal the layers together during another calendering process. Other processes can involve layers being extruded onto a carrier membrane and then put through another calendaring process, or some membranes are made using flashspun technology.

To give an example, our pitched roof underlay Proctor Air® is an SMS product. In other words, it comprises a melt blown layer sandwiched by spunbond layers. This combination allows it to be both vapour permeable and air permeable – reducing condensation risk and providing consistent ventilation.

When one membrane product can offer such different performance compared to another produced using a different manufacturing technique, it is easy to see why assuming all membranes are the same is such a risky attitude.

Request a Sample

Technical Advice

CAD Detail Review

U-Value Calculation

Book a CPD

Specification Check